In medical and aerospace systems, frameless motors are widely used due to their small size and excellent performance. Frameless motors come in several different types, so how can you choose the best one for your requirements?

This article explains the types of frameless motors, their features, and applications to help you decide.

The different types of frameless motor

As there are various types of frameless motors, you have to learn about each of them while choosing the best one. To know more about it, check this article out - The Frameless Motor: What it is, How it works, & Where to use it. Below, I have mentioned them with features and uses; let’s take a look at them.

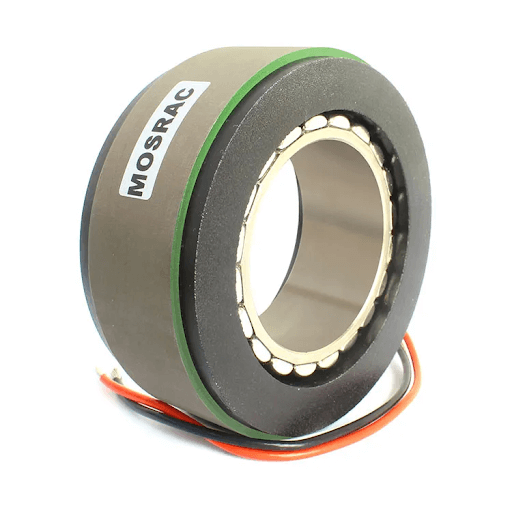

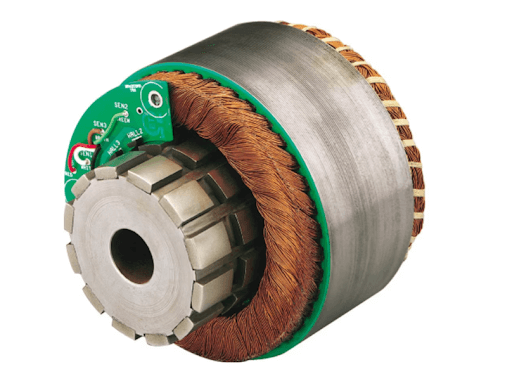

1. Frameless inrunner motor

A frameless inrunner motor is an electric motor without outer housing and with a rotor inside the stator. This is standard for high-performance applications where weight, size, and efficiency matters.

Photo credit: Mosrac

Features/Benefits:

▪︎ Inrunner Design: Rotor inside the stator, better heat dissipation, and higher RPM.

▪︎ High Speed: Inrunner motors can achieve higher speed than outrunner motors, for applications where fast rotation is required.

▪︎ Small and Light: Frameless design means the motor takes up less space.

▪︎ High Power Density: Lots of power in a small package for demanding applications.

▪︎ Precise Control: Like many frameless motors, they offer speed and torque control for high-performance applications.

▪︎ Thermal Management: Inrunner design allows for better thermal management. Stators can be directly connected to cooling systems for improved motor efficiency and life.

Applications:

▪︎ Robotics

▪︎ Drones

▪︎ Medical Devices

▪︎ Electric Vehicles

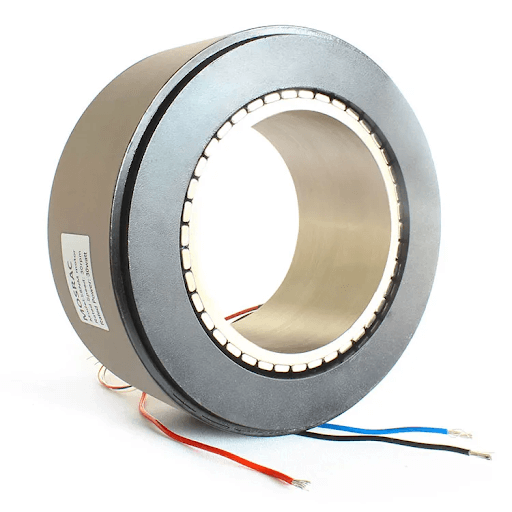

2. Frameless outrunner motor

A frameless outrunner motor is a brushless motor where the stator and the rotor are sold separately, without an external housing. These motors are highly customizable and used in specialized applications where designers want to integrate the motor directly into the mechanical structure of a device. However, if you want to learn details about this motor type, visit A (Frameless) Outrunner Motor: Here's What You Will Learn in 2024.

Photo credit: Mosrac

Features/Benefits:

▪︎ High Torque: Outrunner design allows for more torque due to a larger rotor radius and more magnetic surface area.

▪︎ Compact and Light: Since the motor is frameless, it can be embedded into the machine, reducing space and weight.

▪︎ Low RPM Efficient: Outrunner motors are good for applications that require high torque but lower rotational speed.

▪︎ Customizable: The frameless nature of the motor can be customized to fit your project or system.

Applications:

3. Frameless servo motors series

Frameless servo motors are for applications that require high precision, compact form factor, and direct integration into machinery or equipment. These motors have advanced control of speed, torque, and position with the flexibility of a frameless design.

Photo credit: Cyber-motor

Features/Benefits:

▪︎ High Torque Density: Frameless servo motors have a lot of torque for their size, which is perfect for compact designs.

▪︎ Compact Form Factor: Without the frame, these motors can be embedded into the mechanical system, saving space and weight.

▪︎ Precision Control: Just like traditional servo motors, they can have acceptable position, speed, and torque control.

▪︎ Thermal Management: You can customize thermal management systems for each application for better cooling.

Applications:

▪︎ Robotics

▪︎ Aerospace

▪︎ Medical Equipment

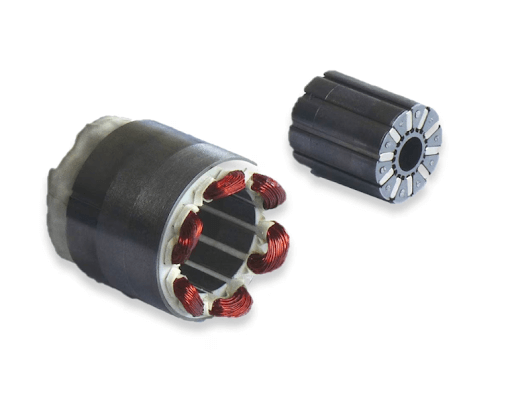

4. Frameless direct drive torque motors

Frameless direct drive torque motors are specialized electric motors for high-speed, high-precision applications. This motor is mounted directly into the machine. This design allows the motor to be mounted directly into the machine’s spindle assembly, so it is perfect for compact and efficient systems.

Photo credit: Mosrac

Features/Benefits:

▪︎ Compact and Light: No external frame, so they fit into tighter spaces and have less overall weight.

▪︎ High Torque Output: Frameless motors deliver high torque, perfect for applications that require both power and precision.

▪︎ Custom Integration: They can be mounted directly into the mechanical system, which has design flexibility.

▪︎ Low Inertia: Enables faster acceleration and deceleration, so they are more efficient machines.

▪︎ Thermal Management: The design allows for better cooling options, which is suitable for high-performance applications.

Applications:

▪︎ CNC Machining

▪︎ Grinding Machines

▪︎ Aerospace

▪︎ Semiconductor Equipment

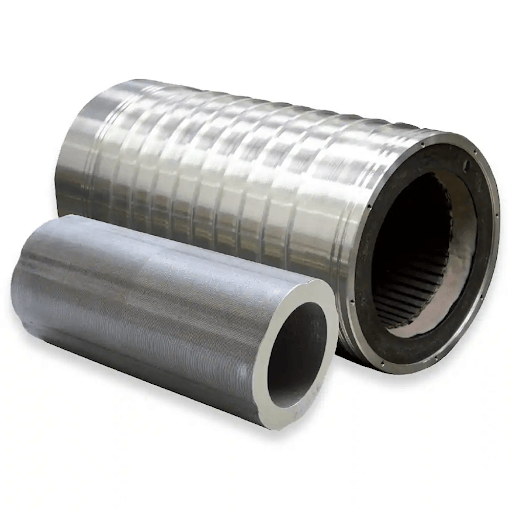

5. Frameless spindle motors

Frameless spindle motors are compact, high-performance motors designed for direct integration into machinery. They consist of separate rotor and stator components. Besides, these motors deliver high torque and speed with minimal cogging. So, spindle motors are mainly ideal for precision applications in robotics and manufacturing.

Photo credit: Parker

Features/Benefits:

▪︎ Efficiency: Frameless spindle motors achieve over 95% efficiency in converting electrical energy to mechanical energy. This high efficiency minimizes energy losses typically associated with traditional motors.

▪︎ Low Noise Operation: These motors operate with minimal noise. So, you can use them for environments where sound levels must be kept low, such as in medical or surgical settings.

▪︎ High Torque Density: They provide a high torque-to-weight ratio. This way, spindle motors have fast response times and provide efficient performance.

▪︎ Reduced Maintenance: Spindle motors have fewer moving parts and no wear-prone components like gears or bearings. So, they typically require less maintenance over their lifespan.

Applications:

▪︎ Industrial Manufacturing

▪︎ Aerospace

▪︎ Medical Equipment

▪︎ Robotics

6. Frameless low cogging servo motors

Frameless low-cogging servo motors are for high-performance applications. These motors deliver precise, smooth motion with minimal torque ripple. Low cogging refers to the reduction of cogging torque. A phenomenon where the motor experiences jerky motion due to the interaction between the stator’s magnetic field and the rotor’s permanent magnets.

Credit photo: Parker

Features/Benefits:

▪︎ Low Cogging Torque: Designed to minimize cogging, these motors provide smooth motion. This is important for high-precision applications.

▪︎ High Torque Density: These motors deliver high torque relative to their size, so they are powerful and compact.

▪︎ Optimized Heat Management: The frameless construction facilitates versatile cooling solutions, improving the motor's efficiency during demanding operations.

▪︎ Elevated Torque Output: These motors provide substantial torque compared to their dimensions. This results in a powerful yet space-saving design.

Application:

▪︎ Aerospace and Defense

▪︎ Industrial Automation

▪︎ Medical Equipment

▪︎ Robotics

7. Frameless spindle servo motors

Frameless spindle servo motors are high-performance motors that can be mounted directly into a machine. Unlike traditional motors, these frameless motors only have a stator and rotor, no housing, bearings, or other components.

Photo credit: Parker

Features/Benefits:

▪︎ Servo Precision: Precise control of position, speed, and torque, ideal for high-performance motion control.

▪︎ High Torque Density: High torque for their size, for demanding applications.

▪︎ Customizable: As they do not have a frame, they can be customized to fit system requirements and design flexibility.

▪︎ Smooth Operation: Low cogging and high-quality bearings for smooth movement, even at low speeds.

▪︎ Efficient Cooling: Frameless design allows for optimized cooling solutions and direct mounting to cooling surfaces.

Applications:

▪︎ CNC Machining

▪︎ Grinding Machines

▪︎ Milling Machines

▪︎ Robotics and Automation

▪︎ Medical Devices

8. Frameless low voltage servo motors

Frameless low-voltage servo motors are compact, customizable motors. These motors are used in applications that require high torque and precise control but with lower voltage inputs, generally below 5V. Like other frameless motors, they only have a rotor and stator without additional mechanical components such as housing, bearings, or encoders.

Photo credit: Parker

Features/Benefits:

▪︎ Low Voltage: They are designed to work with lower voltage inputs, often 5v, for battery-powered or low-power applications.

▪︎ Precise Control: As servo motors, they provide precise control of position, speed, and torque, which is critical for applications that require accuracy.

▪︎ High Torque Density: Despite small and low voltage, they can deliver high torque and are efficient for small but demanding tasks.

▪︎ Customizable: Frameless design allows customization to fit system requirements and more design flexibility.

▪︎ Energy Efficient: Low voltage motors are more energy efficient, especially in battery-powered systems, and they have longer operational times.

▪︎ Smooth Operation: Often has low cogging torque and soft and continuous operation even at low speeds.

Applications:

▪︎ Mobile Robotics

▪︎ Medical Devices

▪︎ Industrial Automation

▪︎ Wearable Technology

▪︎ Aerospace

Final thoughts

Choosing the right frameless motor is key. Whether you need high performance for robotics, automation, or medical devices, each type has its own advantages for different applications.

Mosrac has different types of frameless motors for industrial and commercial use. If you need a frameless motor, see our products and contact us now.

FAQs

1. Are frameless motors more efficient than traditional motors?

Frameless motors are more efficient than traditional motors because of their smaller size and weight, less heat, and mechanical friction losses. Also, these motors come with higher torque density and improve performance in medical and robotics devices.

2. Do frameless motors need special controllers?

Yes, frameless motors often require specialized controllers. Their unique design, lacking a physical frame, necessitates precise control over current, voltage, and position.

3. What maintenance do frameless motors need?

Usually, frameless motors require minimal maintenance as they have fewer moving parts. However, regular visual inspection and removal of dust and debris can increase its performance and longevity. Also, rotor and stator cleaning and bearings lubrication are done per the manufacturer’s specifications.

4. Are frameless motors suitable for robotics?

Frameless motors have a high torque to weight ratio and can be embedded into robotic systems. Basically, they are perfect for applications that require precise control and space efficiency.