Introduction

Choosing the right motor for your industrial applications can be the key to achieving efficiency, precision, and reliability. When it comes to torque motor vs servo motor, understanding their differences and unique strengths is crucial for optimal performance.

A torque motor delivers high torque at low speeds, ideal for direct-drive systems like CNC machines and rotary tables. On the other hand, a servo motor excels in high-precision tasks, offering fast, accurate motion control for applications such as conveyor systems and robotics.

Mosrac provides cutting-edge solutions to meet diverse requirements, helping industries make informed choices between torque motor vs servo motor, based on their unique applications!

Basics of Torque Motors

A torque motor is a type of direct-drive motor designed to produce high torque at low rotational speeds without the need for a gearbox. Operating on electromagnetic principles, it delivers smooth and precise motion, making it an excellent choice for applications where stability, reliability, and low maintenance are essential.

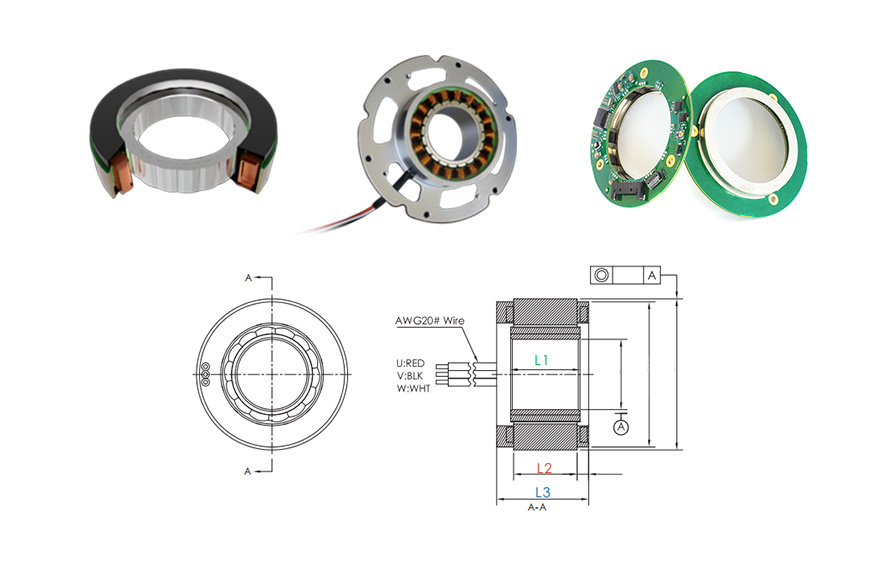

Torque motors are also known as "frameless motors” which means they don't have housings, bearings, or feedback devices.

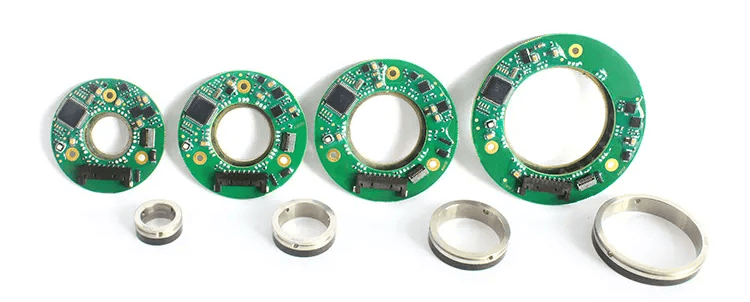

Mosrac Frameless Torque Motors

Torque Motor has the following key features:

▪︎ High Torque Output: Capable of generating substantial force even at low speeds.

▪︎ Direct Drive for Smooth Motion: Eliminates mechanical components like gearboxes, resulting in reduced vibrations and noise.

▪︎ No Gearbox Required: Simplifies design, minimizes wear and tear, and reduces maintenance needs.

Some common applications include:

▪︎ Robotics: Used in robotic joints and arms for precise, torque-heavy operations.

▪︎ Consumer Electronics: Used in smartphones, cameras, and drones for stabilization, zoom, and autofocus.

▪︎ Industrial Automation: Used in assembly lines for precise positioning and handling of components.

▪︎ Medical Devices: Used in surgical robots, prosthetics, and rehabilitation devices for precise movements and controlled force.

▪︎ Semiconductor Application: Used in wafer fabrication equipment for precise positioning and handling of delicate components.

▪︎ Printing Applications: Ideal for CNC machines where stable, accurate rotary positioning is essential.

Furthermore, Frameless Torque Motors manufactured by Mosrac are widely used in aerospace for high-performance actuators, while Housed Torque Motors power medical imaging systems with exceptional precision. These motors ensure seamless integration into custom designs, catering to the unique demands of each industry.

Recommended Reading: Torque Motor - Types, Features, Advantages, Applications and Choosing the Right One

Basics of Servo Motors

A servo motor is a high-performance motor designed for precise control of position, speed, and torque. It operates using a closed-loop feedback system, where sensors continuously monitor output to adjust performance. This real-time correction ensures exceptional accuracy and responsiveness, making servo motors indispensable in automation and robotics.

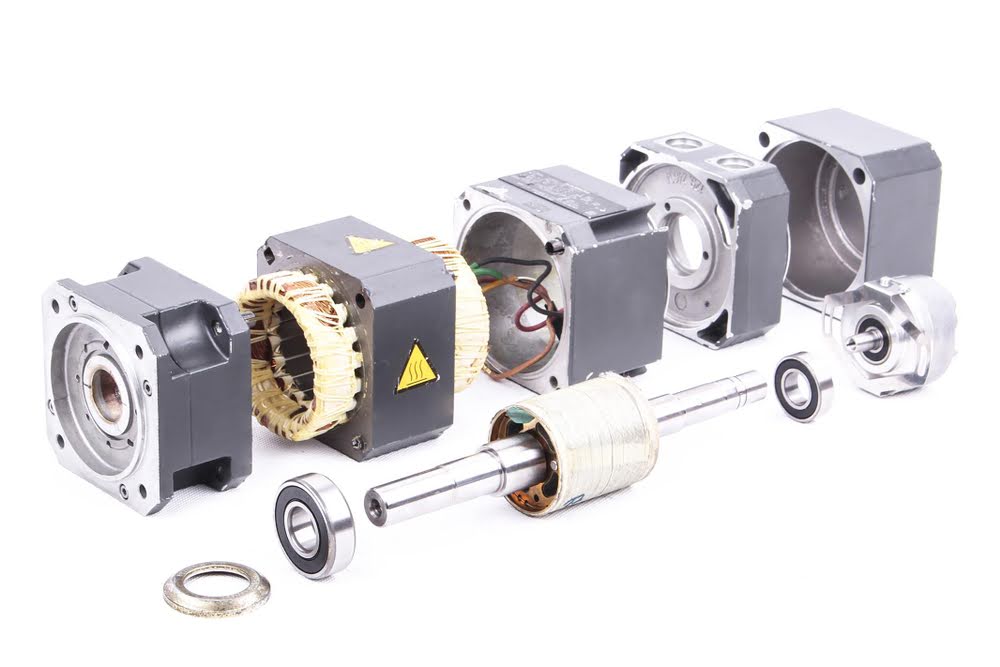

Disassembled Industrial Servo Motor

Servo Motor has the following key features:

▪︎ High Precision and Speed Control: Delivers accurate positioning and rapid motion for dynamic applications.

▪︎ Closed-Loop Feedback: Ensures real-time monitoring and correction, enhancing stability and performance.

▪︎ Compact Design: Small form factor ideal for applications with space constraints.

Some common applications include:

▪︎ Conveyor Systems: Powers efficient material handling with precise speed control.

▪︎ Automated Guided Vehicles (AGVs): Drives navigation systems for autonomous vehicles in warehouses and factories.

▪︎ Industrial Machinery: Enables precise control in packaging, assembly, and textile machinery.

Furthermore, High-Precision Servo Motors manufactured by Mosrac are widely used in the automotive industry for robotic welding systems, ensuring perfect alignment and speed. Similarly, Compact Servo Motors, like U130 Series Frameless Servo Motors are ideal for AGVs in logistics, providing the power and precision needed for seamless operation in tight spaces. These customizable solutions cater to diverse industrial needs, enhancing efficiency and accuracy across sectors.

Comparison of Torque Motors vs Servo Motors

Let’s go through the side-by-side table comparison below:

| Feature | Torque Motor | Servo Motor |

| Torque Output | High torque, optimized for low-speed applications | Moderate torque, ideal for high-speed applications |

| Speed | Limited rotational speed | High-speed capability |

| Precision | Moderate precision for direct-drive systems | High precision with accurate position control |

| Feedback | Often operates without feedback systems | Uses closed-loop feedback for real-time adjustments |

| Maintenance | Minimal, due to the absence of mechanical components | Regular maintenance is required for complex systems |

| Durability | Durable, fewer moving parts reduce wear and tear | Dependable, but more prone to wear due to moving parts |

| Cost | Higher initial cost due to robust build, lower operational cost | Lower upfront cost, higher long-term maintenance expenses |

| Best Applications | Rotary tables, CNC machines, robotics | Conveyor systems, AGVs, industrial automation |

| Examples | U25 Series, U38 Series, U68 Series, U115 Series Torque Motors | Frameless Servo Motors |

Here’s a detailed comparison of features:

▪︎ Torque Output and Speed

Torque motors excel in applications requiring high torque at low speeds, making them ideal for heavy-duty tasks like CNC rotary tables and custom robotics. Servo motors, with their ability to achieve high rotational speeds, are better suited for dynamic applications like high-speed conveyor systems.

▪︎ Precision and Feedback

Servo motors stand out for their precision, leveraging closed-loop feedback systems to provide accurate control over position and speed. Torque motors, while less precise, eliminate the need for additional components like gearboxes, offering smooth motion in direct-drive configurations.

▪︎ Maintenance and Durability

Torque motors require minimal maintenance due to their simple design, lacking gears or belts. Servo motors, with their complex mechanisms, need regular upkeep to ensure consistent performance. In Mosrac, torque motors with their robust construction, are designed for long-lasting operation even in demanding environments.

▪︎ Cost Considerations

Torque motors generally have a higher initial investment but are cost-effective over time due to reduced maintenance needs. Servo motors, while more affordable upfront, incur higher operating costs due to ongoing maintenance. Mosrac offers customizable solutions for both motor types, ensuring the best value for your specific requirements.

With innovative designs, high-performance capabilities, and industry-specific applications, torque and servo motors by Mosrac are setting new benchmarks in efficiency and reliability. Whether you need maximum torque or precise control, our product range is tailored to meet diverse industrial needs.

When to Choose Torque Motors?

Torque motors are specifically engineered to excel in applications demanding high torque at low rotational speeds, with precise and smooth operation in direct-drive systems. Their unique design eliminates the need for intermediate mechanical components like gearboxes, ensuring greater efficiency, reduced maintenance, and enhanced durability. These attributes make torque motors the optimal choice for industries where stability, reliability, and robust performance are critical.

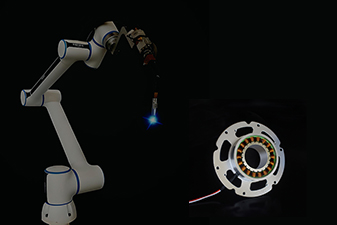

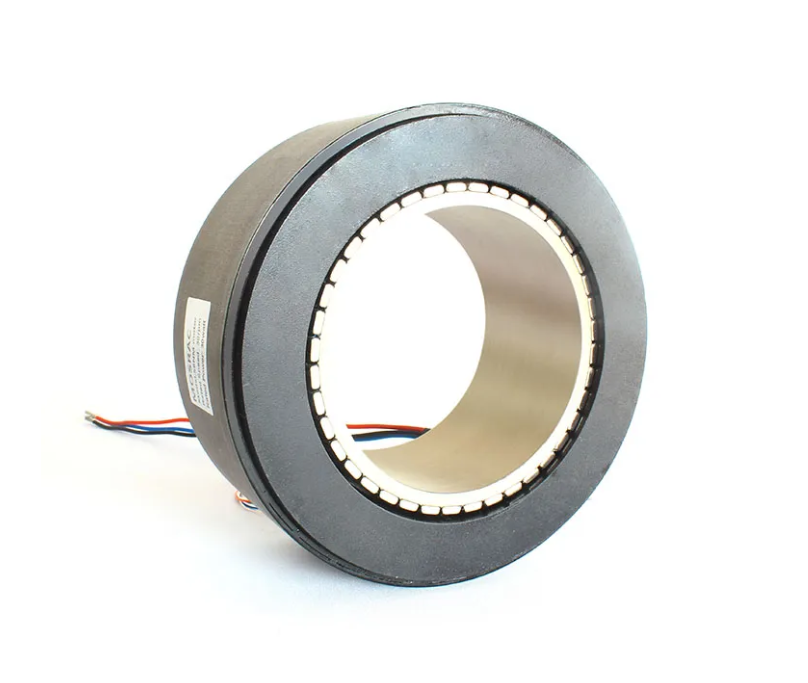

Torque Motor used in Robotic Arms

Our Inrunnerand Outrunner Torque Motors are used in Industries and Applications:

▪︎ CNC Rotary Tables

Torque motors are pivotal in CNC rotary tables, where their ability to provide continuous torque ensures stable positioning and smooth rotary motion. This capability is crucial for high-precision machining tasks such as milling, drilling, and turning operations. The direct-drive functionality of U68 Series Torque Motors minimizes backlash and enhances the accuracy of intricate machining processes.

▪︎ Custom Robotics

In robotics, torque motors are often integrated into robotic joints or actuators, offering the high torque and compact size necessary for precise motion in confined spaces. For example, U25 Series, and U38 Series Torque Motors enable seamless integration into custom designs, ensuring flexibility in robotic arm configurations used in manufacturing, healthcare, and space exploration.

▪︎ Aerospace Applications

Torque motors are widely utilized in aerospace for high-performance actuation systems. Their ability to deliver consistent torque and operate under extreme conditions makes them ideal for applications like satellite positioning systems, gyroscopes, and flight simulators. The direct-drive capability of U76 Series Torque Motors reduces mechanical complexity, which is critical for aerospace systems where reliability and weight reduction are paramount.

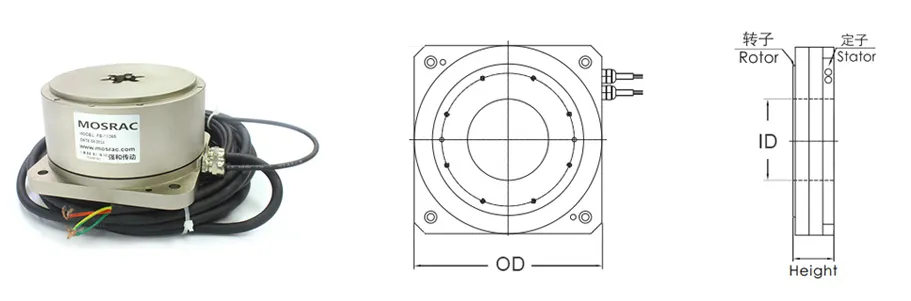

Similarly, DDR motors manufactured by Mosrac include the FE series and FI series, with various size options for different application needs, the OD ranges from 40mm to 375mm.

FE-112 Series Direct Drive Rotary; Specs: Rated Torque: 3Nm and 8.5Nm, Motor Power: 62.9W to 133.6W, Motor Net Weight: 3.2kgs to 4.5kgs.

Torque motors, manufactured by Mosrac are tailored for these demanding applications, offering frameless and housed configurations to suit specific industrial needs. With their advanced electromagnetic design and seamless integration with magnetic absolute encoders, our torque motors ensure unparalleled performance, durability, and adaptability in even the most challenging environments.

Recommended Reading: How to Choose the Right Torque Motor: 14 Essential Criteria

When to Choose Servo Motors?

Servo motors are the go-to choice for applications where precision, speed, and real-time adaptability are essential. These motors operate with a closed-loop feedback system that ensures precise control of position, speed, and torque. This makes servo motors indispensable in high-speed and high-accuracy operations that demand constant monitoring and adjustment.

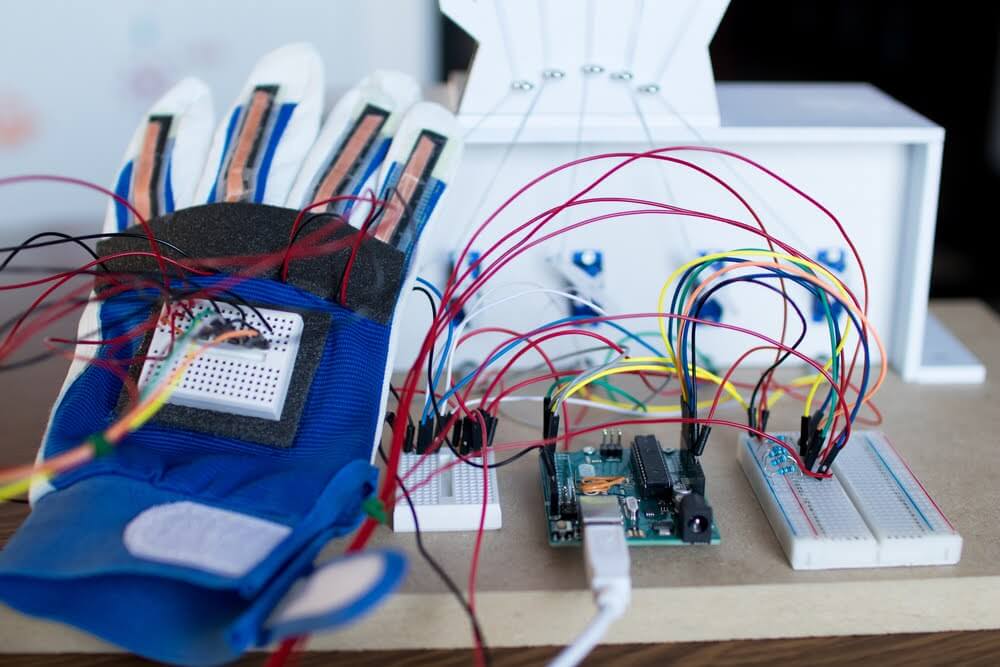

Robotic Hand Controlled by Servo Motors and Gloves with Bending Sensors

Servo Motors are used in Industries and Applications:

▪︎ Packaging Machines

Servo motors are integral to modern packaging systems, enabling synchronized movement and precise control for processes like sealing, cutting, and labeling. Their high-speed capability ensures consistent throughput, while their precision guarantees accurate placement and alignment. U130 Series Frameless Servo Motors excels in these environments, offering the perfect blend of performance and reliability.

▪︎ Pick-and-Place Robots

Servo motors power pick-and-place robots used in assembly lines and material handling. Their ability to deliver rapid and precise movements makes them ideal for handling delicate components in the electronics, automotive, and pharmaceutical industries. Our manufactured servo motors ensure minimal cycle times and precise positioning, enhancing productivity in automated workflows.

▪︎ Printing Systems

In printing systems, where accuracy and speed are critical, servo motors ensure the precise positioning of print heads and substrates. Their high-resolution feedback systems guarantee sharp and consistent outputs, even at high operating speeds. Our servo motors are optimized for these demanding applications, providing reliability and exceptional control in offset, digital, and 3D printing technologies.

Customizable options, including alternative voltage levels and tailored torque-speed characteristics, are available in servo motors to meet specific needs.

U130 Series Servo Motors; Specs: 419-755 W | 5.00-18.00 Nm | 400-1400 rpm | 48 V

One of the latest next-generation frameless motors is hollow-shaft U130 series stator-rotor kits, which offer market-leading torque density and maximum design freedom for structurally integrated drive engineering. Designed with customizable features, they seamlessly integrate into diverse industrial environments, ensuring optimal performance and efficiency across a range of precision-driven tasks.

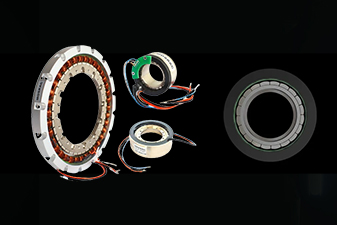

Integration with Magnetic Absolute Encoders

Magnetic absolute encoders are pivotal in enhancing the performance of both torque and servo motors, providing precise feedback on position, speed, and rotational movement. By continuously monitoring and relaying this critical data, encoders ensure motors operate with unmatched precision and efficiency, even in complex industrial environments.

S-Series Magnetic Encoder; Specs: 17-bit High Resolution | ±0.05° Accuracy

Mosrac S-series magnetic encoder is an ultra-thin absolute encoder with multiple output formats and strong anti-electromagnetic interference capabilities. Various sizes are available, suitablefor applications requiring high output accuracy and limited space.

Encoders Enhance Performance in Torque and Servo Motors:

1. Improved Accuracy and Control

Encoders offer real-time feedback, enabling servo motors to adjust their position and speed dynamically, achieving pinpoint precision. For torque motors, magnetic encoders ensure stable and controlled motion, critical for applications requiring consistent torque output.

2. Enhanced Efficiency

The integration of encoders reduces energy waste by ensuring optimal motor performance through continuous feedback, allowing precise adjustments that prevent overloading or underperformance.

3. Fault Detection and Diagnostic

Encoders help identify and rectify performance anomalies, such as misalignment or load inconsistencies, ensuring motors maintain peak functionality and reduce downtime.

Benefits of Pairing Torque Motors with Encoders for Direct-Drive Systems

1. Seamless Integration for High-Torque Applications

Magnetic absolute encoders provide accurate positioning in torque motors used for direct-drive systems, such as CNC rotary tables and aerospace actuators. This eliminates the need for gearboxes while maintaining high torque stability and precision.

2. Enhanced Performance in Low-Speed Operations

Torque motors excel at low-speed, high-torque tasks, and encoders ensure their performance remains stable and accurate, even under varying loads or operational conditions.

3. Maintenance Reduction

Encoders minimize wear and tear by optimizing motor movements, reducing mechanical strain, and extending the lifespan of torque motor systems.

Advantages of Custom Industrial Solutions

1. Tailored Configurations

Mosrac specializes in pairing torque and servo motors with magnetic absolute encoders to deliver custom solutions that meet specific industrial requirements. For instance, our encoders enhance performance in robotics, rotary systems, and medical imaging devices.

2. Innovative Technology

Our magnetic absolute encoders feature robust designs capable of operating in extreme conditions, ensuring durability and reliability. With high-resolution feedback and seamless integration, they elevate the performance of our motors to new heights.

3. Industry-Specific Applications

From aerospace and defence to precision manufacturing, Mosrac’s encoder-integrated motors provide industry-leading solutions that optimize efficiency, precision, and adaptability.

Mosrac magnetic encoders deliver reliable, high-performance for various applications in many industries, from robotics to medical laboratory and equipment, printing to automotive applications, servos, and stepper motors. Explore our range of customizable motors and encoders to unlock new possibilities for your applications.

Conclusion

Torque motors and servo motors each serve distinct purposes in industrial applications. Torque motors excel in high-torque, low-speed tasks, such as CNC rotary tables and robotics, while servo motors dominate precision and high-speed operations like packaging machines and pick-and-place robots. Understanding these differences is essential to selecting the right motor for your specific needs.

When deciding between a torque motor and servo motor, consider the application’s requirements for torque, precision, speed, and long-term maintenance. Both motors offer unique benefits, and the choice often depends on the operational demands and desired outcomes.

At Mosrac, we provide advanced motor solutions, including frameless and housed configurations, enhanced with advanced magnetic absolute encoders. Whether you require standard models or custom solutions, our products are engineered to exceed expectations. Explore our comprehensive range at Mosrac and find the perfect motor for your next project!

Frequently Asked Questions

1. What is the main difference between torque motor and servo motor?

Torque motors deliver high torque at low speeds, while servo motors excel in precision and speed control with closed-loop feedback systems.

2. Which is better for CNC machines: torque motor or servo motor?

Torque motors are ideal for CNC rotary tables due to their direct-drive design, while servo motors suit high-speed machining with precision.

3. Can torque motors be customized for specific applications?

Yes, Mosrac offers customizable torque motors, including frameless and housed models, tailored for aerospace, robotics, and industrial automation needs.

4. Why are magnetic absolute encoders used with torque and servo motors?

Encoders enhance precision, real-time performance feedback, and stability, ensuring optimal motor efficiency in applications like robotics and CNC systems.

Looking for a Custom Solution?

Tell Us about your requirements and our application engineers will help you find the right solution today!