A robot motor transforms electrical energy into mechanical energy and makes a robot able to move, rotate, and operate. The type of robot motor affects the robot’s performance, speed, accuracy, and power consumption. To meet the requirements of a robot, various types of motors are used. Selection of the right motor for a robot depends on a deep understanding of the specific requirements of the robot’s intended tasks.

Robots use different motors, such as DC motors, servo motors, and stepper motors with unique features. Choosing the right motor is critical for a robot’s efficiency in completing its assigned tasks. For example, a robot designed for speed will be different from the one designed for accuracy.

Speed: The maximum speed of brushless DC motors can be from thousand to tens of thousands of rpm. The rotational speed of stepper motors is determined from the frequency of its input pulse. Stepper motors have a high torque in the low-speed range and a low torque in the high-speed range.Brushless DC motors and stepper motors are good choices for high speed robotics applications. They provide high efficiency, smooth motion, and high torque output. Collaborative robots use these kinds of motors for assembly operations.

Accuracy: Servo motors are useful for applications requiring stable power output in industrial robotics. Servo motors give accurate control and flexibility for multi-axis movement of robots. Servo motors and stepper motors provide high accuracy and are suitable for robotics uses. Industrial robots use these kinds of motors for welding, painting or palletizing while mobile robots for navigation.

MOSRAC provides high-quality frameless motors and encoders with excellent design and performance for robots. These motors and encoders are cost-effective for robots. These are well-suited for robotics applications because of their reliability, fast speed and acceleration, precise positioning, and repeatable movements.

In this article, we will discuss the most common types of motors used in robots with a basic understanding of their types, features, and applications. It will also highlight the key considerations for choosing an appropriate motor for robotics operations.

What purposes do robot motors serve?

Robot motors perform the goal of causing movement in robots. They provide power to the wheels, legs, or other parts of the robot. Robot motors implement the following purposes:

1. Higher Energy Efficiency:

Energy efficiency has been an important factor because of the higher integration of robots into daily life and industries. Brushless DC motors are more energy efficient than brushed DC motors. BLDC motors can transform more electrical power into mechanical power than a brushed motor for the same input power because of the absence of friction of brushes. Brushless motors are more efficient at higher power density and longer battery life.

Key Properties of BLDC Motor:

● Higher Efficiency: BLDC motors maintain high efficiency, usually ranging from 80 to 95%.

● Low Friction: The lack of brushes in the BLDC motor minimizes friction and energy loss.

● Less Heat: Brushless motors generate less heat and sound and contain enough energy for the rotor to run the load.

● Higher Electromechanical Conversion Rates: BLDC motors have electromechanical conversion rates of 85–90%.

● Advanced Speed Control: BLDC motors can easily alternate between low and high speeds.

● Higher Speed Limit: BLDC motors can run at higher speeds than brushed motors.

2. Low maintenance and higher longevity:

An important purpose of a robot motor is its maintenance requirements and longevity. For example, brushless motors need less maintenance than brushed motors since they have fewer moving parts and are ideal for long-term uses.

3. Better Precision Control:

Servomotors and stepper motors provide higher precise location and speed control in robotics applications.

4. High Performance:

Some robot motors provide high torque and speed output, making them appropriate for high-performance robotic applications.

5. Rapid Response:

Robot motors need to be regulated quickly to meet variable motion requirements. It is very important for applications that need quick startup, stopping, or movement changes.

6. Low Noise:

Many robot motors operate smoothly with reduced noise and are appropriate for noise-sensitive requirements.

7. Better Flexibility:

Robot motors should be flexible on various motion trajectories and speed requirements, making them very flexible for different applications.

Most common types of motors used in robots

Different motors provide advantages and are suitable for specific robotics applications. In the following sections, we have discussed 8 types of motors that are commonly used in robots.

1. Servo Motors:

A: Overview:

Servo motors are special types of DC motors that provide accurate control over angular location, speed, and torque.

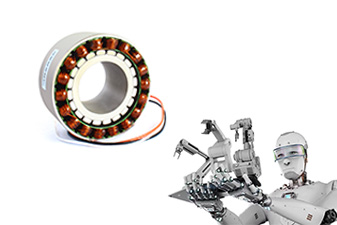

Figure 1: Servo motor

B: Working Principle:

The main components of a servo motor are a DC motor, a feedback sensor, and a control circuit. A pulse-width modulated signal from the control circuit adjusts the motor’s location.

C: Key Properties:

● Higher Accuracy: Servo motors can adjust location precisely, which is very important for the requirements of good movements.

● Feedback Technique: Built-in sensors give real-time feedback for accurate change.

● Fixed Rotation: Standard servo motors usually have a rotation scale of 180°.

D: Applications:

● Robotic arms use servo motors to control joint angles and movements accurately.

● Pan-tilt techniques use these motors to regulate the location of cameras or sensors.

● These are used to regulate the opening and closing of robotic grippers.

E: Advantages vs Disadvantages:

| Advantages | Disadvantages |

| High accuracy | Costlier than DC motors |

| Excellent for controlled movements |

2. Stepper Motors:

A: Overview:

Stepper motors are a type of brushless DC motor that splits a whole rotation into many equal steps. These motors move in separate steps to meet the requirements of accurate rotations in 3D printers or robotic arms.

Figure 2: Stepper Motor, image credit: islproducts

B: Working Principle:

Stepper motors run by energizing coils through specific steps, causing the movement of a rotor. Every step shows a fixed angle of rotation for highly controlled movement. They operate in full-step, half-step, or micro-step modes according to accuracy.

C: Key Properties:

● Accuracy: High

● Open-Loop Operation: No requirement for a feedback system and simple control circuits.

● Torque: Stepper motors keep their location steady when not moving, which is important for stable positioning applications.

D: Applications:

● Printhead and bed use stepper motors for regulating the movement, such as 3D printers.

● Cutting tools or workpieces use these motors for locating precisely, such as CNC machines.

● Cameras for time-lapse photography use these motors to adjust their movement, such as camera sliders.

E: Advantages vs Disadvantages:

| Advantages | Disadvantages |

Appropriate for precision tasks | Hard to control |

| High torque at low speeds | Inappropriate for high-speed uses |

3. Brushless DC Motors:

A: Overview:

Brushless DC motors provide a major advancement over usual DC motors based on efficiency and longevity. These motors are more reliable and have a high operational life without brushes. These motors are appropriate for continuous-use robots like drones or industrial robots.

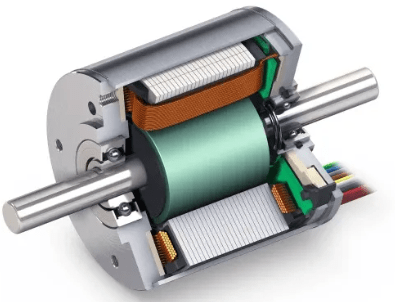

Figure 3: Brushless DC Motor; Image credit: kinmore

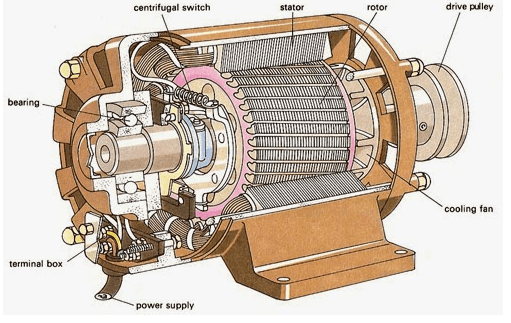

B: Working Principle:

A BLDC motor uses an electronic commutation instead of brushes. It includes a rotor with fixed magnets and a stator with electromagnetics. A cycle of controlled pulses from the stator coils, which are maintained by an electronic controller, runs the rotor.

C: Key Properties:

● Higher Efficiency: There is low friction and heat generation in BLDC motors that produce higher efficiency and longevity.

● Higher Torque: These motors can generate high torque at low speeds for robotic applications.

● Low Noise Operation: These motors have reduced noise and smooth operation compared to brushed DC motors.

D: Applications:

● These motors provide the required thrust for quadcopters and other flying robots, such as drones.

● Ground-based robots, such as robotic vehicles, use these motors for driving the wheels or tracks.

● These motors have applications for quick and accurate movements.

E: Advantages Vs. Disadvantages

| Advantages | Disadvantages |

| High efficiency | More complex |

| Low maintenance | Costlier than brushed motors |

| Longer lifespan |

4: Linear Motors:

A: Overview:

Linear motors create linear motion rather than rotational motion. Without mechanical transmission systems, such as gears or belts, linear motors operate on direct movement along a straight path.

B: Working Principle:

A linear motor follows the same principles as a rotary motor. The stator and rotor produce a direct force along the length of the motor while setting up a linear model.

C: Key Properties:

Direct Drive: Linear motors can produce direct linear motion without extra mechanical elements.

Higher Accuracy: These motors are capable of very accurate positioning for high-precision applications.

Higher speed and acceleration: These can attain high speeds and quick acceleration according to the applications.

D: Applications:

● Robotic arms use linear motors for accurate positioning.

● Pick-and-place machines use these motors for the movement of the components quickly and accurately in manufacturing lines.

● Automatic transport systems use these motors to provide smooth and accurate movement.

5. AC Motors:

A: Overview:

AC motors operate on AC power and maintain high levels of power because of their robustness and capacity.

B: Working Principle:

AC motors transform alternating current into mechanical motion through electromagnetic induction. There are two types of AC motors, synchronous and asynchronous.

Synchronous Motors: Synchronous motors operate at a fixed speed whatever load is. The relation between a rotating and a fixed magnetic field causes the operation of the motor with a constant speed. The stator of the synchronous motor generates the rotating magnetic field and the rotor generates a fixed magnetic field.

Figure 4: AC Synchronous Motor

Asynchronous Motors: Asynchronous motor operates at lower speed than synchronous speed. An asynchronous motor has two main parts, such as stator and rotor. AC supply generates a rotating magnetic field around the stator.

Figure 5: AC Asynchronous Motor

C: Key Properties:

● High Power: AC motors provide significant power for heavy-duty applications.

● Constant Speed: Synchronous AC motors maintain a constant speed under various loads.

● High Durability: AC motors are robust and can handle harsh operating situations.

D: Applications:

● Industrial Robots: Large robotic arms use AC motors for driving heavy machinery.

● Conveyor Systems: Conveyor belts use these motors for powering in automated systems.

● Automation Equipment: Various types of automated manufacturing equipment use these motors.

E: Advantages vs Disadvantages:

| Advantages | Disadvantages |

| High efficiency | Inappropriate for accurate control or small robot applications |

| Robust | |

| Appropriate for large-scale robots |

6. Pneumatic Motors:

Overview:

Pneumatic motors use compressed air to create rotational motion.

Key Properties:

● Lightweight

● High power-to-weight ratios

Applications:

● Mobile robots that need fast movements use pneumatic motors.

Advantages vs Disadvantages:

| Advantages | Disadvantages |

| Pneumatic motors are lightweight with high power-to-weight ratios | These motors need a reliable source of compressed air |

| These motors are appropriate for fast movements | Lower power density compared to electric motors |

7. Piezoelectric Motors:

Overview:

Piezoelectric motors run according to the piezoelectric effect, where the material becomes deformed through the application of an electric field.

Applications:

Micro-robotics use these motors for accurate movements on a small scale.

Advantages:

● These motors run on a small scale and provide precise movements.

Disadvantages:

● These motors have low-power output applications.

● These motors can be more difficult to control compared to usual motors.

8. Magnetic Field Motors:

Overview:

Magnetic-field motors follow the principles of magnetism to create motion.

Applications:

● Mobile robots use these motors for accurate position control in medical robotics or laboratory automation.

Advantages:

● These motors provide high accuracy in position control.

Disadvantages:

● These motors need complex control algorithms for higher performance.

● These have higher costs.

Powerful Motors for Robotic Applications:

1. Robotic Arms:

Robotic arms use these robot motors for industrial robots and collaborative robots to manage operations in material maintenance, assembly, and transportation.

2. Mobile Robots:

Robot motors are important for mobile robots, such as drones, unmanned vehicles, and delivery robots for navigation, reliability, and propulsion systems.

3. Medical Robots:

Medical robots use these motors in surgical robots and diagnostic equipment to attain precise movements.

4. Aerospace:

Robot motors are important in adjusting and navigating space probes, satellites and aircraft.

5. Automated Production:

These motors are useful in automated production lines for different applications, such as packaging and inspection.

6. Personal Robots:

Personal robots, toys, and consumer electronics products use these motors.

7. Healthcare Industry:

In the healthcare industry, robotic systems use robot motors for high accuracy, such as robotic surgery or automated drug dispensing.

8. Manufacturing Industry:

Manufacturing robots use robot motors to lift heavy objects or assemble parts quickly. Robot motors provide the required power and efficiency to run production lines smoothly.

9. Service Robots:

Service robots use robot motors for services like vacuuming, lawn mowing, or food delivery.

Selection Criteria for an Appropriate Robot Motor

Consider the following criteria to choose the right motor for a robot for different applications.

1. Motor Type:

Choosing the right type of motor is an important step for robotics applications. Various motors, such as stepper motors, servo motors, and brushless DC motors (BLDC motors), are appropriate for robotics applications. These motors have advantages and disadvantages.

2. Important Application Requirements:

Some essential requirements of a robot motor, such as torque, speed, precision, and power consumption, need to be evaluated. Select the load capacity and motor power to run the robot's movements and operations.

3. Improved Power Supply and Efficiency:

Estimate the power supply and efficiency of the motor in transforming electrical energy into mechanical output. An efficient motor will assist the robot’s whole energy savings and longer battery life.

4. Physical Size and Weight:

There should be enough space available in the robot's design for motor placement. Fit a motor within the constraints of the robot's structure to maintain an acceptable weight-to-performance ratio.

5. Higher Integration with Control System:

Consider some important factors, such as the motor's communication protocol, feedback capabilities, and programming requirements to ensure integration and efficient control of the robot’s movements. Some motors require special controllers, while others can integrate with general-purpose controllers.

6. Low Cost:

The cost-performance ratio of different motors needs to be evaluated. Select the motor that provides the highest value for application without degrading the quality.

7. Low Maintenance and Higher Reliability:

The required maintenance for a motor is an important issue. Brushed DC motors may need brush substitutes. Brushless motors provide higher lifespans and lower maintenance requirements.

8. Atmospheric Issues:

There are some atmospheric conditions, such as temperature, humidity, and dust resistance, that need to be considered. Some kinds of motors can handle harsh conditions. Choose a motor that can handle the atmospheric conditions and continue reliable performance.

MOSRAC Robot Motors and Encoder We Recommend

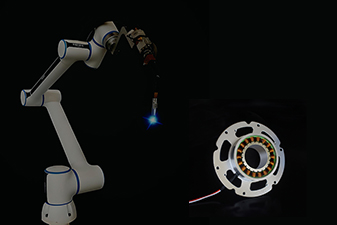

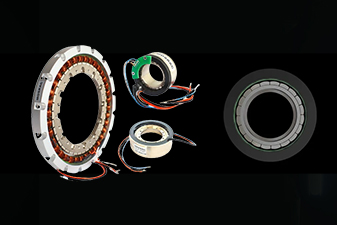

Robots require components that can assist them in driving accurately. The key features of MOSRAC frameless motors are high torque, speed, size, and temperature. These torque motors provide the most adaptability and are lightweight.

MOSRAC U38 series, U50 series, and U60 series frameless motors are widely used in robots. These motors provide a very compact design, excellent precision, better overload capacity, high torque density, and lightweight. They possess industry-leading performance and are cost-effective.

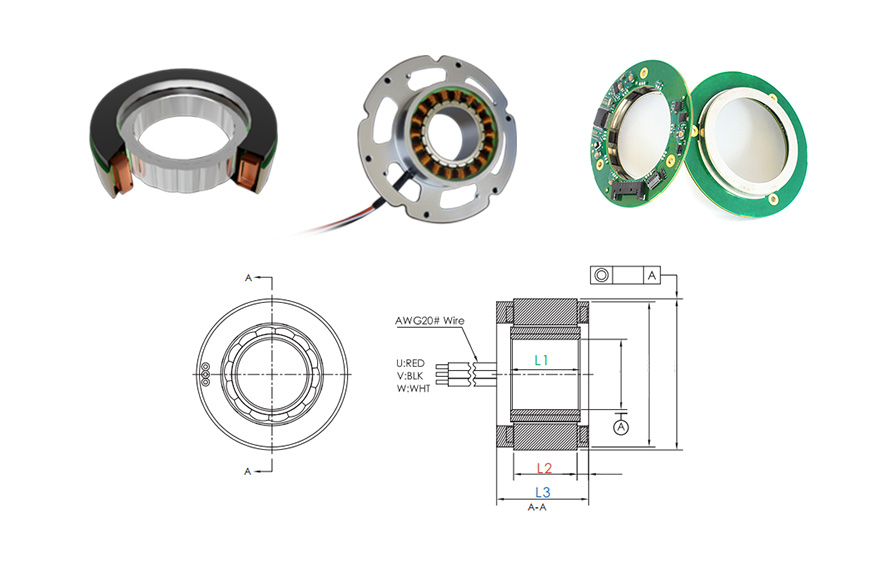

Figure 6: MOSRAC Frameless Torque Motor for Robot Applications

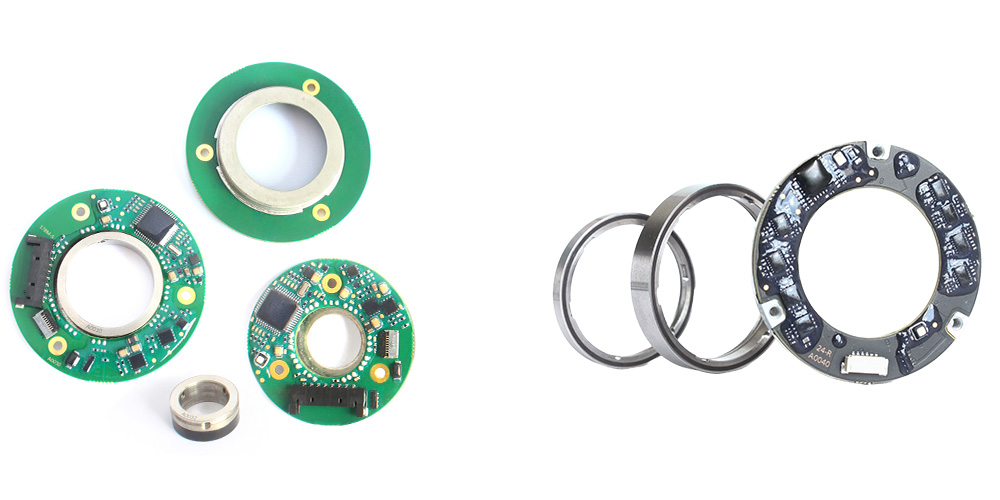

MOSRAC produces a high-quality T-Series Magnetic Dual Encoder to fulfill the customer’s requirements for excellent location measurement and motion control of robotics. The wide range of encoders from MOSRAC provides accurate feedback. Their compact and lightweight design provides an adaptable system and higher integration for various types of robots. The low power consumption of our encoders makes them appropriate for the requirements of battery-powered robotics.

There is a huge application of MOSRAC’S T-Series Magnetic Dual Encoder in robot-integrated joint applications. These encoders have photoelectric-like resolution and accuracy and high protection for atmospheric effects. The main features are the world's most compact, dual 24-bit high-resolution, and ±0.01° accuracy.

Figure 7: MOSRACT 17-bit & 24-Bit High-Resolution Magnetic Absolute Rotary Encoder

Conclusion:

Motors play a vital role in robotics applications because of their performance and efficiency. The achievement of a robotic application primarily depends on the accurate selection and structure of motors. It is essential to have a deep understanding of different motors and their capacities in robotics technology.

MOSRAC helps their valuable customers with the right selection of motors for robots according to their requirements. MOSRAC frameless motors and encoder are suitable for different robotics applications. These are appropriate for robotics applications because of their reliability, fast speed and acceleration, precise positioning, and repeatable movements.

Got a question about robot motors? Contact me by email.

FAQs

1. Do robots use AC or DC motors?

Robots can use both AC (alternating current) and DC (direct current) motors based on the requirements. Robots usually use DC motors, but sometimes they use AC motors for

specific reasons. Some criteria, such as speed, control requirements, and the design of the robot, are important in selecting the motor.

DC motors have huge applications in robotics because of their battery power, variable speed, and torque. They operate in wheeled robots for propulsion for the change of speed and direction through the change of the voltage and polarity applied to them.

AC motors do not have huge applications in robotics. Stationary industrial robots use AC motors if steady high-speed rotation is needed. AC motors are usually more difficult to control, and their speed is usually determined by the frequency of the supplied AC power.

2. What type of motors do universal robots use?

Universal robots may use many kinds of motors, but they use servo motors mostly because of their higher resilience and capacity than other types. Servo motors have high torque density, adaptability, high accuracy, control, programmability, reliability, and safety.

3. What is the best motor for a robot?

It is important to consider the specific requirements of the application, such as speed, torque, precision, and efficiency to select a motor for a robot. Other factors, such as the size and weight of the motor, as well as its power requirements and control mechanisms, are also quite important.

Robots may use various types of motors according to their properties and benefits. These motors can be DC motors, servo motors, stepper motors, brushless DC motors, AC motors, and linear motors. However, servo motors are more widely used than other types of motors in a robot. It includes a finite range of motion and robotic applications where accuracy is more important than speed.

4. Which motor is used in the robotic arm?

A robotic arm is composed of an arm, controller, end effector, sensor, and drive. A robotic arm uses DC, stepper, and servo motors.

There are two types of DC motors, such as brushed and brushless. The efficiency of a brushed DC motor is usually 75%–80%. It has high torque at low speeds and is easy to adjust. But it generates noise because of the brushes used to rotate the machinery. A brushless DC motor is less noisy and can keep the torque maximum continuously. It is difficult to control and needs a special regulator sometimes. There is always a choice of attaching a gearbox to the system to generate more torque for robotic arm uses.

Stepper motors have maximum torque at low speeds and are easy to control and are perfect for robotic arm applications. They are noisy and become hot for drawing maximum current continuously. These motors have low top speeds and can create critical problems in robotic arm applications.

The robotic arm uses servo motors for accurate positioning. They are appropriate for robot arms because accuracy is more important than speed. Servo motors are highly reliable for high-speed performance. They can give high torque at high speed and maintain dynamic load variations.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

Any questions or comments about Frameless Motors, Direct Drive Rotary Motors, and Encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!