An outrunner motor is a type of frameless motor. This motor stands out with its unique design. The motor rotor is positioned outside the stator. This outrunner motor feature offers high torque and low maintenance. All these make it a top choice for high-power applications.

In this article, I will explore everything you need to know about outrunner motors, from how they work and their features to tips on choosing the right one for your project.

What is outrunner motor?

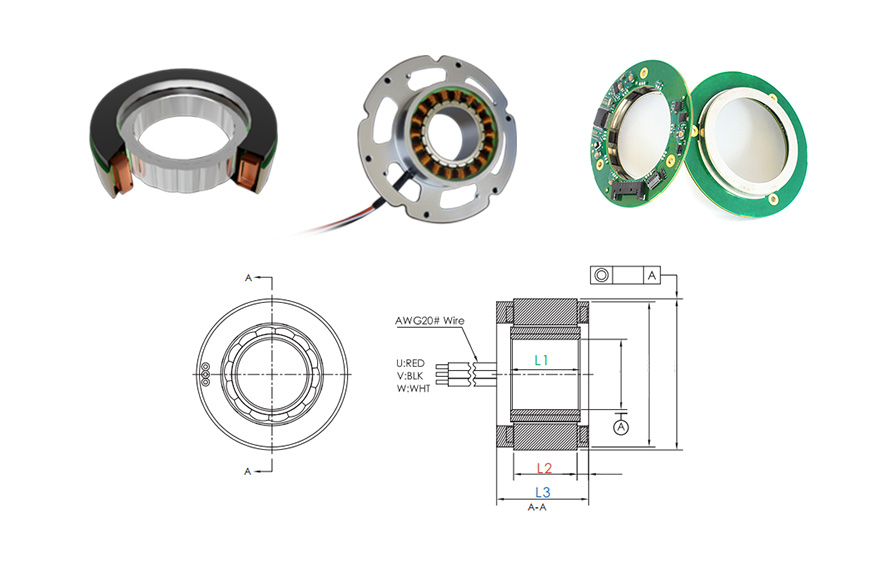

The example of outrunner motor example: frameless outrunner torque motors

Outrunner motors are a unique variation of frameless motors. Their innovative design sets them apart, with the rotor positioned centrally on the outside and the stator. This design optimizes the motor's torque output and enhances cooling efficiency.

Outrunner motors are suitable for high-performance or high-torque applications. As the rotor rotates around the fixed coil, its larger diameter delivers more power at RPM than a traditional setup.

Besides, outrunner motors can deliver high torque with low weight. This feature makes them particularly attractive for robotics and industrial automation, which demand a lightweight yet robust solution.

The features of outrunner motor

Here are some features of the outrunner motor:

1. Compact design

Compact design often conveys elegance and efficiency in technology, especially outrunner motors. These specialized motors typically exhibit a unique structural arrangement allowing size reduction without compromising performance. Because their rotors are located on the outer casing rather than the inner core, they can achieve high torque at low speeds.

2. High efficiency

High efficiency in outrunner motors reshapes the electric propulsion landscape. It delivers streamlined performance that challenges traditional designs. This configuration reduces energy losses associated with heat generation and increases overall system efficiency.

As a result, outrunner motors achieve impressive power-to-weight ratios that appeal to electric and industrial applications.

3. Low maintenance

Unlike traditional inrunner motors with complex internal parts, outrunner motors offer a low-maintenance solution. Their design simplicity and operational efficiency provide a sense of relief to users, ensuring reliable performance without frequent servicing.

Besides, outrunner motors have a rotating outer casing and fixed inner components. This configuration allows for better cooling while reducing wear and tear, reducing the risk of overheating during heavy use. Users can enjoy longer breaks between required services.

4. Integrated thermal sensor

Integrated thermal sensors offer seamless integration into motor designs. Besides, it allows for the real-time monitoring of operating temperatures. It works for maintaining optimal performance and preventing overheating. This capability enhances longevity and ensures efficiency.

5. Low cogging

Low cogging, a notable feature of outrunner motors, significantly increases their performance in precision applications. The outrunner motor maintains an impressively smooth and consistent rotation, improving responsiveness and reducing vibration. These motors are ideal for sensitive tasks such as robotics, where stability is paramount.

6. High torque

Outrunner motors are suitable for applications requiring high torque and impressive power output in a compact form factor. This design has the stator on the inside and the rotor on the outside. It allows for a larger diameter, giving more torque at lower RPM.

7. Durability

Outrunner motors are built with more robust materials like (high-grade aluminum and advanced composites) and enhanced cooling features that significantly extend their lifespan. Their external rotor configuration allows for better heat dissipation. This design contributes to longevity and ensures consistent reliability under demanding conditions.

8. Precious performance

Outrunner motors are revolutionizing performance in applications like electric vehicles. When necessary, gear reduction can be combined with compact planetary, harmonic, or cycloidal gears with low. It provides an immediate response to variations in speed and position requirements from the drive while offering exceptional torque density.

How outrunner motor works?

An outrunner motor has two main parts: the stator (inside) and the rotor (outside). The stator has wires that create a magnetic field when electricity flows through them.

The rotor, which surrounds the stator, has magnets. When the stator's magnetic field changes, it pulls on the magnets, making the rotor spin. Since the rotor is on the outside, it directly turns the motor's shaft.

The motor's controller carefully times the electricity flow, making the magnetic field rotate smoothly, which causes the rotor to spin. The speed of the spin can be controlled by how fast the electricity switches on and off.

Outrunner motor suitable for - Application

Outrunner motors, with their versatility and high efficiency, are not limited to a single application. Their potential spans various sectors, inspiring engineers and professionals to explore their use in electronics, industrial automation, medical devices, robotics, aerospace, and UAVs.

1. Electronics

Consumer electronics continue to evolve, driven by an insatiable demand for innovation and convenience. It's a product of an outrunner motor. Here are some sectors of consumer electronics:

• Wearable Technology

• 3D Printers

• Home Automation

• CNC Machines

• Gaming And Virtual Reality

2. Industrial automation

Industrial automation is evolving rapidly, driven by integrating innovative technologies that increase efficiency and accuracy. Outrunner motors have a unique design that maximizes torque while minimizing size, enabling faster response times and reducing energy consumption. This aspect makes them ideal for automation tasks ranging from pick-and-place operations to driving conveyor systems.

Industrial automation caters to various operational needs in multiple sectors, such as:

• Printing and Labelling

• Marking and Engraving

• Material Handling

• Packaging and Assembly

3. Medical device

Integrating outrunner motors into medical devices is revolutionizing patient care. Especially in applications involving mobility aids and precision surgical equipment. These motors, known for their high torque-to-weight ratio and efficiency, enable the design of lightweight yet powerful devices. Outrunner motors make them suitable for various medical device applications:

• Surgical Robots

• Instruments

• Rehabilitation Device

• Laboratory Automation

• Radiation Therapy Equipment

• Medical Assemble Automation

• Imaging System

4. Robotics

As robots evolve, components help them move in exact and powerful ways. Outrunner motors are reliable because there are no spare transmission parts. They can achieve very fast speed and acceleration. Outrunner motors make them suitable for robotics applications:

• Mobile Robot

• Humanoid Robot

• Industrial Robot

• SCARA Robot

• Exoskeleton

Consideration when choosing outrunner motor?

When considering an outrunner motor, there are some leading factors to consider, such as:

1) Speed

The speed of an outrunner motor is primarily determined by its KV rating, which stands for RPM per volt. This rating indicates how many revolutions per minute (RPM) the motor will achieve for each volt applied. Here is the equation of KV rating:

Motor Speed (RPM)= KV rating x Voltage

For Example

if you have a motor with a KV rating of 1000 and you apply 11.1 volts, the motor speed would be:

1000 KV x 11.1 V = 11,100 RPM

2) Size and weight

Size also affects power output and weight-to-thrust ratio, which optimizes performance in various applications.

Outrunner motors usually indicate numbers like '22-05'. The first number, 22, indicates how comprehensive the motor is, and the second number, 05, indicates the height. A larger motor typically exhibits increased torque, allowing for better acceleration and handling during demanding maneuvers.

3) Power

The power of an outrunner motor is a critical factor in determining how much work the motor can do. Power is typically measured in watts (W) and is a product of the voltage supplied to the motor and the current it draws.

Motor Power Formula:

Power = Voltage (V) x Current (A)

For Example:

For example, if a motor operates at 12 volts and draws 20 amps, the power output is:

12V x 20A = 240 watts

4) Pole count

The number of poles directly affects the motor's speed and performance. Generally, higher pole counts provide better high torque and low speed. They also offer smoother operation due to increased magnetic interaction.

If your application requires precise power production at low RPM, choosing a motor with high poles may be advantageous.

For instance, by naming criteria of the motor, you can identify its pole count:

| Naming Of the Motor | Pole Count |

| High-speed motors | Two poles |

| Medium-speed motors | Four poles |

| Low-speed motors | Six poles |

| Ultra low-speed motors | Eight poles |

KV rating

The KV rating indicates how many revolutions per minute the motor will rotate when 1 volt is applied with no load. A higher KV rating is suitable for high speed but low torque, while a low KV rating is Suitable for applications requiring high torque and low speed. Here is the equation of the KV rating:

KV= Motor RPM/ Voltage

How can I maintain my outrunner motor?

Clean: Use compressed air or a soft brush to clean out dirt, dust, or debris from the motor, especially in tight spots. Keep the magnets and windings clean for optimal performance.

Regular Inspection: Over time, vibration and environmental factors can cause cable wear or damage. This possibly leads to electric shorts that compromise your motor efficiency. Regularly check for fried or exposed wires. Because minor obstacles can lead to unexpected performance problems. Consider using thermal-squeezing tubing as a preventive measure. It simply strengthens existing wiring and protects against elements.

Bearings: Listen for unusual noises, such as grinding or squealing, indicating worn-out bearings. Spin the motor by hand to feel for any roughness or resistance. If the bearings are not sealed, apply a small amount of bearing oil or grease. Be cautious not to over-lubricate, as excess lubricant can attract dirt.

Check Magnet Position: Ensure that the magnets on the rotor are securely attached and have not shifted. Misaligned magnets can cause the motor to become unbalanced. If you notice any shifting, use high-temperature epoxy to reattach the magnets.

Proper Storage: Keep the motor in a dry, dust-free environment to prevent rust and corrosion. Store it in a temperature-controlled area to protect it from damage due to extreme heat or cold.

The advantages of outrunner motor

• Outrunner motors typically have better efficiency at low speeds.

• They provide greater torque at lower RPM.

• The outer rotor design allows for better cooling due to increased surface area, which helps prevent overheating during operation.

• With fewer internal components than traditional motors, outrunner motors can be simpler to manufacture and maintain.

• Outrunner motors tend to operate at lower RPMs for a given power output, which further contributes to their longevity.

The disadvantages of outrunner motor

• Outrunners often perform best within a narrow speed range, making them less versatile for some high-speed applications.

• The exposed rotor can be more susceptible to physical damage.

• Outrunner motors can tend to be more expensive than traditional alternatives due to their advanced design and materials used in manufacturing.

Outrunner motor vs. inrunner motor- which is better?

Choosing between an outrunner and an inrunner motor depends on the specific application and the desired performance characteristics. Both types have pros and cons, making each better suited for different scenarios.

Outrunner motors are typically better due to their higher torque at lower RPMs. They are suitable for Robotics, Medical devices, Industrial, and Electronics applications.

On the other hand, inrunner motors are better suited for high-speed applications where RPM is more critical than torque. They are particularly suitable for space-constrained applications to meet special engineering projects, perfectly matching your facility spacing and industry needs.

Here's a comparison to help you decide which might be better for your needs:

| Comparison | Outrunner | Inrunner |

| Diameter | Larger | Smaller |

| Length | Smaller | Larger |

| RPM | Lower | Higher |

| Torque | Higher Torque | Lower Torque |

Choose the best outrunner motor from Mosrac

Mosrac offers the best quality frameless outrunner motors with various options of sizes, speeds, weights, and power to perfectly match your needs.

We have 15+ years of experience in manufacturing frameless outrunner motors. Along with this, we have 30+ professional engineers to ensure motor quality. Also, we offer customization based on your inquiry.

Besides, we are working with a bunch of brands worldwide. So, you can order from anywhere in the world to get the best quality outrunner motor.

The list of outrunner frameless torque motor from Mosrac Motor:

| Model | ID (mm) | OD (mm) | Height (mm) | Rated Torque (N.m) | Rated Current (A) | Rated speed (rpm) | Voltage (v) | Weight (kg) |

| UE1406 | 14.9 | 5 | 6.25 | 0.01 | 0.59 | 850 | 12 | 0.004 |

| UE2208 | 22 | 9 | 8.5 | 0.03 | 0.66 | 800 | 12 | 0.012 |

| UE2506 | 25.3 | 10 | 6.2 | 0.04 | 0.66 | 792 | 12 | 0.012 |

| UE3306 | 33.4 | 14 | 6.2 | 0.06 | 0.81 | 950 | 12 | 0.022 |

| UE4009 | 40 | 22 | 9.5 | 0.07 | 0.79 | 1325 | 12 | 0.024/0.032 |

| UE4013 | 40 | 22 | 13.7 | 0.11 | 0.53 | 363 | 12 | 0.036/0.047 |

| UE4913 | 49 | 25 | 13.5 | 0.21 | 0.79 | 343 | 16 | 0.078 |

| UE4918 | 49 | 25 | 18.5 | 0.28 | 0.59 | 238 | 16 | 0.11 |

| UE5819 | 58.6 | 24 | 19 | 0.76 | 1.12 | 221 | 24 | 0.167 |

| UE5829 | 58.6 | 24 | 29 | 1.26 | 1.28 | 221 | 24 | 0.281 |

| UE6815 | 68 | 36 | 15.5 | 0.73 | 1.19 | 182 | 24 | 0.156 |

| UE6830 | 68 | 35.5 | 30.5 | 1.77 | 7.4 | 504 | 36 | 0.345 |

| UE9014 | 90 | 58.5 | 14 | 1.60 | 1.75 | 130 | 24 | 0.206 |

| UE9019 | 90 | 58.5 | 19 | 2.16 | 17 | 1800 | 24~48 | 0.313 |

| UE10933 | 109 | 78 | 33 | 6 | 4 | 140 | 24 | 0.576 |

Conclusion

Outrunner motors offer unique advantages that make them a compelling choice for industrial, medical device, electronics, and robotics applications. Their design allows for greater torque at lower speeds, significantly enhancing efficiency and performance.

If you need an outrunner motor or a customizable application, contact us now.

Frequently Asked Questions

1. Do I need a special ESC for outrunner motors?

Yes, to ensure optimal performance, you will need a brushless ESC compatible with the voltage and current ratings of your chosen outrunner motor.

2. Are there any safety precautions when using outrunner motors?

Always follow manufacturer guidelines regarding voltage limits and usage; wear safety goggles during testing or operation due to potential propeller hazards.

3. How does an outrunner motor differ from an inrunner motor?

Unlike inrunner motors, where the rotor spins inside the stator, outrunners have their rotor on the outside, providing better cooling and higher torque at lower RPMs.

4. How can I increase the lifespan of my outrunner motor?

To extend its lifespan, use appropriate battery sizes to avoid overheating, ensure proper ventilation during operation, and prevent exposure to moisture or corrosive environments.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

Any questions or comments about Frameless Motors, Direct Drive Rotary Motors, and Encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!