Are you looking for high-quality motor encoders? This article provides thorough information and analysis on the different types of motor encoders, their characteristics, uses, and benefits.

Introduction:

Motor control systems rely heavily on motor encoders. A closed-loop feedback change precisely controls their motor speed and position. Variable speed drives with higher-quality motor control performance improve quality for the most practical applications. There are numerous options for motor encoder designs, such as incremental, absolute, optical, magnetic, and others.

The choice of motor encoder depends on several important factors, including the type of motor, application, and mounting configuration. Motor encoders are widely used in various industries, including robotics, automation, manufacturing, medical devices, aerospace systems, and more.

MOSRAC provides high-quality encoders, including absolute encoders with excellent design and performance for motors. These are well-suited for industry applications because of their reliability, cost-effectiveness, fast speed and acceleration, precise positioning, and repeatable movements.

This article will cover a basic understanding of motor encoders' types, characteristics, and uses and emphasize the critical factors to consider when selecting one for industrial applications.

What are Motor Encoders?

An electromechanical device called an encoder transmits an electrical signal for control and speed. It converts motion from mechanical to electrical. Encoders manage essential parameters, such as closed-loop feedback or closed-loop control systems. Motor encoders give the motor control system feedback to determine the motor's location and speed.

Motor encoders monitor important parameters such as position, RPM, speed, and distance.

Two key motor encoder technologies exist.

▪︎ One has to do with the output of an incremental motor encoder, which changes the motor shaft's speed.

▪︎ The output of an absolute motor encoder, which shows the motor shaft's speed, is the other.

There are many different types of motor encoders, including incremental and absolute, optical and magnetic, hollow and with shafts, etc.

Components of Motor Encoders:

1. Shaft:

The motor shaft is connected to the encoder. Once rotated, the shaft transmits the motion to the encoder's internal components.

2. Disc:

The disc mounts to the motor shaft. The disc has patterns that can communicate with sensors to produce electrical signals.

3. Sensors:

When the shaft rotates, sensors detect modifications in the disc’s patterns and transform these modifications into electrical signals.

Types of Encoders for Motor Systems:

▪︎ Incremental Encoders:

A: Overview:

Motor control systems employ incremental encoders to determine how to move the motor and how many steps are needed. Incremental encoders are affordable and easy to use.

B: Components:

The primary parts of an incremental encoder are the circuit, phototransistor assembly, disc with labels, and light source.

C: Working Principle:

Incremental encoders operate by generating pulses about an index or reference point. For accurate shaft tracking, each pulse displays a small angular displacement.

D: Applications:

Incremental encoders are great for many industrial applications that require high speed and accuracy.

▪︎ Absolute Encoders:

A: Overview:

Absolute encoders are essential for motor control systems to provide precise location data. They offer high accuracy in a power outage or system shutdown, which is crucial for high reliability.

B: Working Principle:

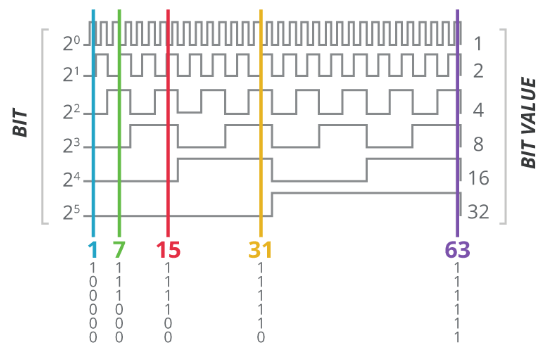

Absolute motor encoders display the shafts' angular location, direction, and speed. They give each relative shaft location a code, which shows the shaft's position during a complete rotation. This code is crucial for a precise location without losing sight of it.

C: Applications:

Uses where operation requirements cause positional data over many rotations.

D: Types:

Absolute motor encoders come in two varieties: single-turn and multi-turn.

Single-Turn Absolute Encoders:

These encoders give control systems the motor shaft's angular location in a single revolution, providing a distinct code for each location. They are suitable for applications involving restricted shaft rotation.

Multi-Turn Absolute Encoders:

These encoders provide information, such as the total number of shaft revolutions. They give the control system information about the motor shaft's angular position and the number of revolutions. Absolute multi-turn encoders count the number of 360° turns and perform absolute operations. Within several revolutions, they provide a distinct code for each location. It is suitable for applications involving continuous shaft rotation.

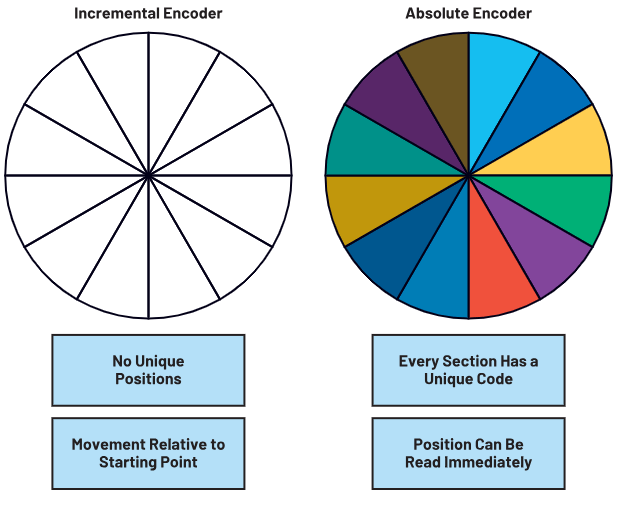

Figure 1: Incremental and Absolute Encoder

Why is an absolute encoder a preferred choice over an incremental encoder?

An absolute encoder displays the correct location in real-time, which is why it is a better option than an incremental encoder. With the increasing digitization of systems, the primary advantage of employing an absolute encoder is the ability to get a real-time position with minimal latency.

To determine the location, an incremental encoder tracks each pulse using external circuitry. When using an absolute encoder with external circuitry, there will be some latency in the location selection process. Because absolute encoders use an error-checked code, they are less susceptible to noise than binary encoders. It is workable to incorporate multiple absolute encoders into a single system.

However, incremental encoders cause pulse counting. Absolute encoders explain the reading with less processing power. In order to view the outputs from many devices, incremental encoders need more processing power.

Figure 2: Generation of digital words by absolute encoders for each position.

Most Popular Types of Motor Encoders:

Several critical factors, including the type of motor, the application that requires closed-loop feedback, and the mounting architecture, influence the type of motor encoder used.

▪︎ AC Motor Encoders:

AC motors apply encoders to regulate speed. Incremental encoders play a vital role in stopping an AC motor at a desired location and changing the angle and location of a motor-driven device.

▪︎ Servo Motor Encoders:

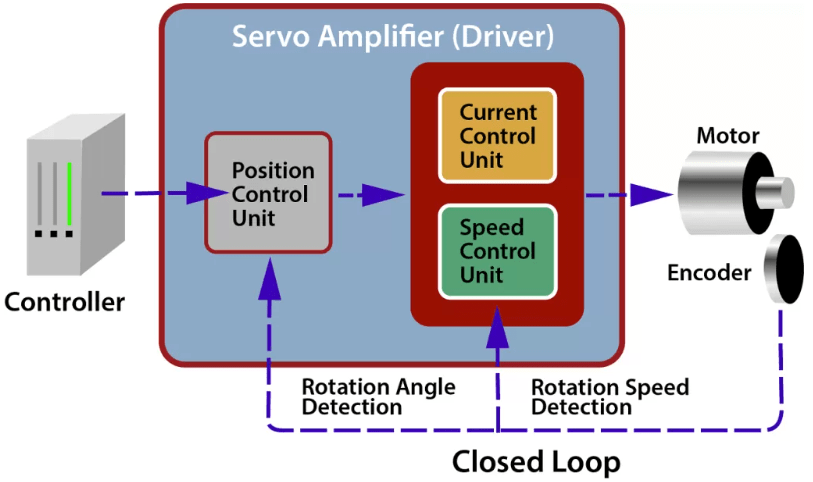

A servo motor has a negative feedback control, making it one of the most versatile. Servomotors are used to achieve high levels of process precision and repeatability. Servo motor encoders provide closed-loop feedback systems for increased accuracy. A servo motor encoder is a sensor that measures a three-phase servo motor's rotational location, speed, and movement. The servo motor encoder provides precise feedback information to the motion control system by converting mechanical motion into electrical signals.

Figure 3: Diagram of basic servomechanism with closed-loop feedback

The relationship between servo motor and encoder:

The load is powered by the three-phase servomotor. To achieve high-precision motion control, the control system receives location feedback information from the servo motor encoder, which tracks the motor's rotation. The encoder sends feedback data, which the control system compares to the desired position. It controls how much power the motor sends to a spot. The system is more reliable thanks to the closed-loop control technique. Servo motors and encoders work together to improve the system's performance.

▪︎ Stepper Motor Encoders:

Stepper motor encoders improve stepper motor control. For speed control, stepper motors are equipped with an incremental motor encoder. With the step angle, they provide precise feedback regarding the motor shaft's location.

▪︎ DC Motor Encoders:

A DC motor's stator generates a magnetic field. DC motor encoders can manage DC motor speed. They use methods to determine the rotor's speed and closed-loop feedback to regulate speed precisely.

Selection Criteria of a Motor Encoder:

1. Signal Type:

Motor encoders provide information by using signals pertaining to an object's location. Analog encoders apply 0–10 V and 4-20 mA. They are preferred because they can work with industrial controllers.

2. Compatibility:

Selecting motor encoders that are suitable for interacting with the automatic industrial systems is crucial.

3. Protection:

Protection enables the motor encoders to function in challenging operating conditions, such as high temperatures caused by motor heating.

4. Mounting Options for Motor Encoders:

A: Shafted Motor Encoders:

A shafted encoder provides motor feedback by connecting to the motor's shaft. This feedback produces electrical separation in shafted motor encoders. A long motor shaft is required for a shaft encoder to mount securely. Because a weak coupling alters the angle of the shaft, it can impair a motor's performance.

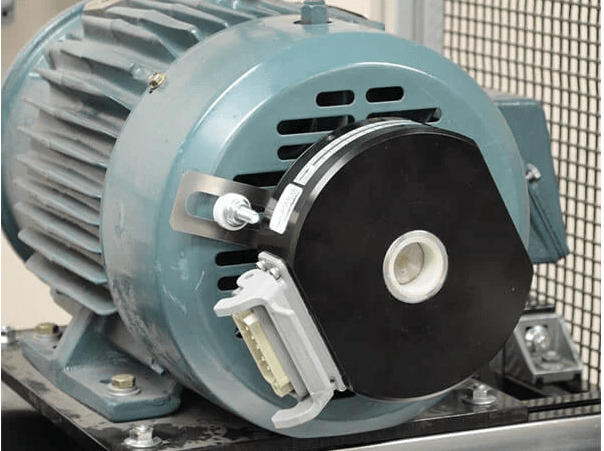

B: Thru-Bore and Blind Hollow Shaft Encoders:

Both types of encoders are simple to install. Steel Thru-bore motor encoders that are adjustable and do not offer electrical isolation can be mounted to the motor shaft using a pass-through shaft collar. Most blind hollow shaft and thru-bore motor encoders have housing structures and duty bearings. These are often inexpensive.

Figure 4: Hollow Shaft Encoder

C: Modular Motor Encoders:

Modular motor encoders are encoder disks mounted to the shaft without a bearing assembly. Because of the smaller number of mechanical parts, these encoders are inexpensive and small. Because of the absence of bearings, these encoders run without starting torque at very high speeds.

D: Ring-Mount Motor Encoders:

These encoders are impervious to vibration, shock, and contaminants. They work well for heavy-duty applications like stronger motors with stronger frames. Because they use coarse resolution, ring-mount encoders are ideal for feedback on speed and movement.

Comparison of Motor Encoders:

Applications for motor encoders depend on particular needs, including price, power, speed, and accuracy.

To select the best motor encoder for an application, it's critical to understand how they differ.

1. Induction Motor Encoders:

Application:

The purpose of induction motor encoders is to control the speed and motion of induction motors.

Working Principle:

Magnetic or optical sensors determine an induction motor's speed and direction.

Advantages:

▪︎ Dynamic design

▪︎ Suitable for applications requiring high torque and speed

▪︎ Economical

Disadvantages:

▪︎ Less accurate than other types

▪︎ Less suitable for precise positioning applications

2. Servo Motor Encoders:

Application:

Suitable for robotics, CNC machines, and automation systems, among other applications requiring precise placement.

Working Principle:

They provide precise control by providing extensive feedback on servo motors' position, velocity, and movement.

Advantages:

▪︎ High accuracy

▪︎ Fast response times

▪︎ Suitable for closed-loop control systems

Drawbacks:

▪︎ More expensive than alternative varieties

▪︎ Complex control algorithms are needed

3. DC Motor Encoders:

Application:

DC motor encoders are widely used in consumer electronics, robotics, and printers.

Working Principle:

They use optical or magnetic sensors to control movement and supply input for DC motor rotation

Advantages:

▪︎ Compact size

▪︎ Low cost

▪︎ Suitable for a wide range of applications

Disadvantages:

▪︎ Has less torque and speed than other types

▪︎ Needs additional gearing for greater accuracy

4. Stepper Motor Encoders:

Application:

Stepper motor encoders precisely control speed and location in robotic systems, CNC machines, and 3D printers.

Working Principle:

They use methods like optical or magnetic sensing to give feedback on direction and location.

Advantages:

▪︎ Increased accuracy

▪︎ Ease of synchronization with control systems

▪︎ Suitability for both closed-loop and open-loop changes

Disadvantages:

▪︎ Produces less torque at high speeds

▪︎ Requires more power than other types

Advantages of Motor Encoders:

A: Higher Accuracy:

One advantage of motor encoders is that they offer precise location feedback for precise changes and motorized system monitoring.

B: Greater Reliability:

By operating steadily, they enhance the performance and dependability of electromechanical systems.

C: Greater Adaptability:

To offer flexibility and scalability, motor encoders integrate with various motor types for various applications

Future Prospects for Motor Encoder Technology:

There is much room for innovation and progress in this field. Advancements will enhance motor encoder performance and reliability in materials science, sensor technology, and signal processing.

In the future, intelligent features like real-time communication, adaptive control algorithms, and predictive maintenance will enhance the effectiveness and functionality of motor encoders used in industrial automation.

▪︎ Faster Transceivers with Lower Latency:

Transceivers with lower latency will gain feedback data and respond to control loops faster.

Research from Rockwell 1 for encoders and encoder communication ports mentions an increase of 20% per year in transceivers for feedback communication. Single-Pair Ethernet (SPE) transceivers are used to enhance 100 Mbps communications for two wires (IEEE 802.3dg standard 100BASE-T1L)1. The purpose of this research is for encoder drive connection with low latency ≤1.5 µs.

References:

1Dayin Xu. “100BASE-T1L for Motor Feedback Communication.” Rockwell Automation, May 2022.

▪︎ MEMS Accelerometers:

Motor encoders use MEMS accelerometers to give machines vibration feedback, which improves quality control. It is beneficial to attach a MEMS accelerometer with an encoder to give the controller vibration feedback. The MEMS vibration data contributes to the system's improved performance.

Challenges:

1. Environmental Problems:

Environmental problems such as temperature fluctuations, vibrations from machinery, and electromagnetic interference can impair motor encoder performance.

2. Selection Criteria:

Several elements are crucial when selecting motor encoders for particular applications, including resolution, precision, operating environment, and communication interface adaptability.

Check Out Our MOSRAC Absolute Encoders:

MOSRAC absolute encoders are crucial for motors that must be precisely located for safety and quality reasons. Because they can store and output digital values for every location, they are helpful in automation systems. When there is no power, they can offer information. MOSRAC absolute encoders can improve production flow and minimize issues in assembly line manufacturing.

Robot motors use MOSRAC absolute encoders to give accurate feedback on where products are on assembly lines. Servo motors use MOSRAC absolute encoders to eliminate the need for the U, V, and W channels. DC motors use MOSRAC absolute encoders for accurate positioning.

MOSRAC absolute encoders are suitable if position feedback is required due to operational safety concerns. Choosing the criteria for the absolute encoder is crucial.

MOSRAC offers products and specifications to help customers select the best absolute encoder for motor applications.

▪︎ S-series Magnetic Encoder:

The S-series magnetic encoders are ultra-thin absolute encoders with various output formats. They are strong at blocking electromagnetic interference, with an accuracy of ±0.05° and a high resolution of 17 bits. They may come in various sizes. Their limited space and high output accuracy make them useful.

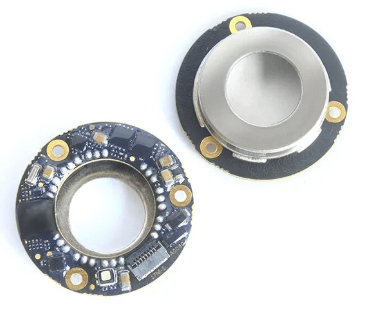

Figure 5: MOSRAC S-Series Magnetic Absolute Position Encoders

▪︎ T-series Magnetic Dual Encoder:

They include MOSRAC motor pattern magnetic technology with photoelectric-like resolution. This dual encoder is highly resistant to environmental interference and has a high resolution of 24 bits. It is accurate to within ±0.01°. Joints integrated into robots employ this kind of dual encoder.

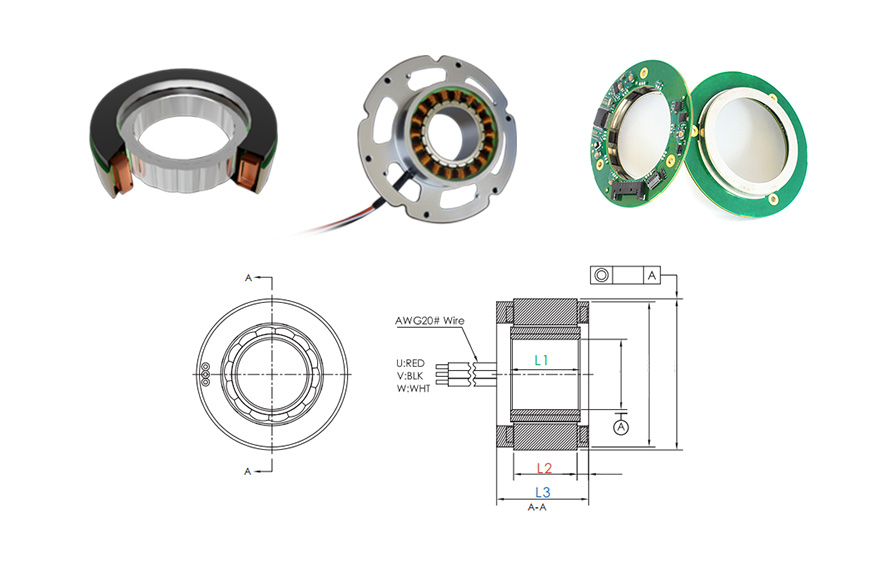

Figure 6: MOSRAC T-Series Magnetic Dual Encoder

Conclusion:

Encoders improve the efficiency, accuracy, and stability of various motor applications. Motor encoders monitor the motor shaft's position and speed and provide closed-loop feedback signals. They make it possible to measure a motor system's moving parts precisely. Many applications exist, ranging from 3D printers to robotics.

Enhancement of knowledge regarding the functioning and principles of motor encoders, electromechanical systems, industrial automation innovation, and efficiency is necessary. In contemporary industrial automation, motor encoders are crucial for precise motion control and feedback methods.

MOSRAC encoders are suitable for a range of motor applications. Based on their needs, MOSRAC assists its esteemed clients in selecting the ideal encoder motors for their applications.

It offers encoder information tailored to clients' unique needs.

Could you send me an email with inquiries concerning motor encoder types?

Motor Encoder FAQ's

1. What is the operating principle of a motor encoder?

Using optical or magnetic sensing systems, a motor encoder converts mechanical motion into electrical signals. These signals offer feedback that provides information about position, speed, and rotational movement, allowing precise adjustment and observation of motorized systems.

2. What is a motor encoder essential for precision motion control?

Motor encoders are crucial for precise motion control because they provide feedback on motor rotation's position, velocity, and motion. This feedback lets control systems adjust motor parameters in real-time to guarantee precise location and direction.

3. What is the difference between the operational principles of incremental and absolute encoders?

Incremental encoders generate pulses using a reference point that enables incremental location feedback. Without needing a reference point, absolute encoders provide absolute location feedback by assigning a distinct digital code to each motor shaft location.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

Any questions or comments about Frameless Motors, Direct Drive Rotary Motors, and Encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!