Frameless torque motors are small but have an incredible speed. They are best for precise movement and efficient performance of your robot joints. So, how do you choose a frameless torque motor for robot joints?

That's where we will help you with this article.

We've discussed the torque motor features for a robot joint in depth here. So, read the whole article without skipping to make the right decision.

What is a frameless torque motor?

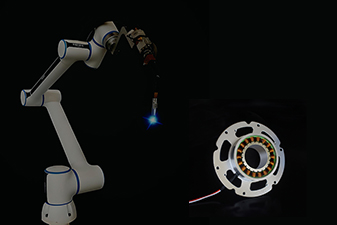

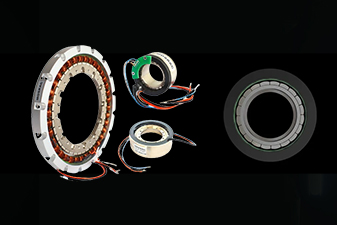

Frameless motors and DD motors from Mosrac

Outrunner frameless motors

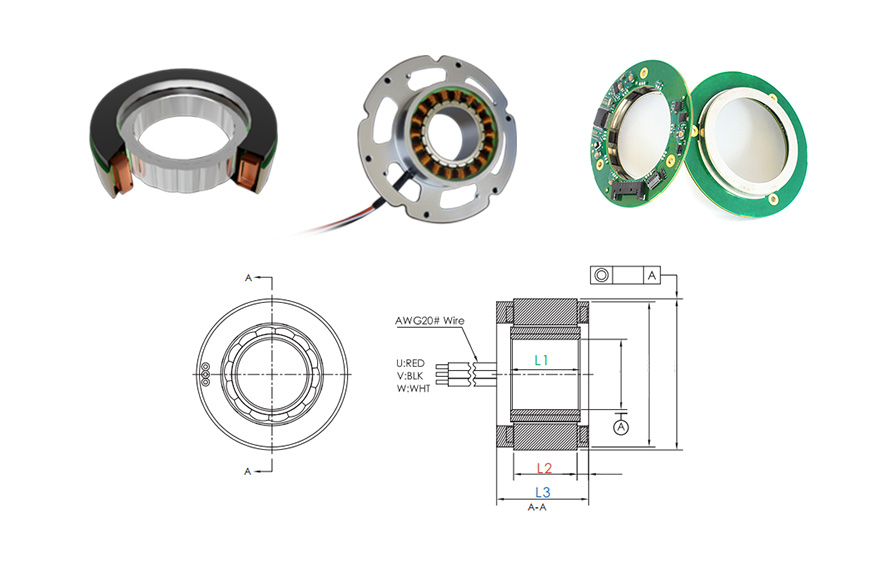

Unlike conventional motors, frameless torque motors are designed with no house or frame. The rotor and stator are the two key components of a frameless torque motor. They help the frameless motors generate torque without the need for a frame.

This way, the torque motor ensures precise control with high performance. Therefore, these motors can be used in robotics, aerospace, medical devices, and advanced industrial machinery. To learn details about frameless motors, check out The Frameless Motor: What It Is, How It Works, & Where To Use It.

Things to consider to picking the best frameless torque motor for a robot joint

Let's look at some common things you must check to choose the best frameless torque motor for a robot joint.

1. Technical specifications

Check some technical facts about frameless torque motors, such as size, power, and noise level.

1.1 Motor size

The motor size determines its power and torque capabilities. Smaller motors are often used for lightweight applications, while larger motors are suited for more demanding tasks. Therefore, you should consider your robot joint's space constraints and physical size requirements while choosing a frameless torque motor.

1.2 Rated torque, power, & speed

Rated torque is the continuous torque that the motor can produce without overheating, helping to maintain performance. However, higher-power motors typically deliver better performance but require more robust power supplies. In addition, speed determines how fast the motor can rotate. So, ensure these ratings align with your application's needs.

1.3 Sinusoidal torque vs. angle curves and phase balance

Sinusoidal torque and angle curves describe the relationship between a motor's torque output and the rotor angle. A well-balanced motor with sinusoidal torque characteristics provides the consistent performance necessary for precise robotic movements. You won't find their information in detail. However, you can request the data from the company.

Phase imbalances can lead to uneven torque production and additional wear on the motor components. This equal electrical load distribution is vital in applications requiring high precision, such as robotic arms for delicate tasks.

1.4 Motor constant

The Motor Constant indicates how powerful the motor is compared to its size. A higher number means the motor is more robust and performs better with less heat generation. So, check the motor constant to make sure it's strong enough. For the best result, you can research and compare different models to find the right fit for your specific needs.

1.5 Low cogging

The robot joint does not require cogging torque, so you must choose a frameless torque motor with low cogging. This will reduce vibration and increase efficiency. On the other hand, a high cogging frequency is better to control than a low frequency.

1.6 Noise level

The noise produced by a frameless torque motor during operation is irritating and disturbs others. If the robot is for a noise-sensitive atmosphere, especially for medical purposes, select motors with a noise level of 40-50 decibels. This will ensure quieter operation and increase the user experience.

2. Thermal management

2.1 Integrated thermal sensor

An integrated thermal sensor can monitor the motor's temperature in real-time. This feature helps in proactive thermal management by alerting you to overheating issues before they cause damage. The sensor data can adjust operational parameters or activate cooling mechanisms. Thus, you can ensure the motor remains within safe temperature limits.

2.2 Thermal resistance and thermal time constant

Thermal resistance refers to the motor's ability to transfer heat flow out from its internal components. Lower thermal resistance means better heat management, which prevents the motor from overheating and increases its lifespan.

Again, the thermal time constant measures how quickly the motor can respond to changes in temperature. A lower constant number means the motor cools down and warms up quickly. And a higher number means it stays at one temperature for longer. So, choose a low thermal time constant motor to ensure a fast response of the robot.

2.3 Electrical time constant

The electrical time constant of a frameless torque motor indicates how fast it can respond after pressing a button. A lower electrical time constant means the motor can react more swiftly to commands. It is vital for high-speed and high-precision tasks like the robot joint.

So, check the motor's time-constant specifications and ensure they align with the operational demands of your robot joint.

3. Practical considerations

Let's see some practical factors when choosing a motor for robot joints that match your budget.

3.1 Motor integration

Now, examine the motor's compatibility with your robot's control system and feedback mechanisms. This will ensure smooth motion control. Choose a motor with easy installation options. Also, its form factor must align with your existing robot's design.

3.2 Customization

With the customized option, you can tailor the frameless torque motor to specific robotic applications. So check if your manufacturers offer customized features before confirming your order. Some options you can customize are torque outputs, winding types, and shaft configurations.

In addition, you can customize motor performance factors like speed, response time, and more. Therefore, you can tailor the motor based on the robot's operational requirements.

3.3 Price & warranty

The cost of the motor should match the project's budget constraints without compromising on quality and performance. Therefore, you can compare prices among manufacturers and understand what is included. For instance, see if they offer additional parts or support services.

Furthermore, if you want years of peace of mind, you should buy a frameless torque motor with long warranty periods. Look for their terms and conditions to see if they will fix any problems during the warranty period.

Why use a frameless torque motor for robot joint?

Below, we have mentioned a few reasons you should use a frameless torque motor for robot joints. Take a look at them-

1. Compact and lightweight design

Frameless torque motors do not require extra mechanical worms, belts, etc., which makes them lighter than others. This design will save space and reduce the load on the robot structure. So, the robot will be more flexible and move faster.

2. High precision and torque density

With high precision and torque density, frameless motors ensure accurate control of robotic joints. Their direct drive design reduces the need for extra gears and transmissions. Also, they eliminate backlash and improve the accuracy of the robot's movements. So, these motors can be used in industrial, medical, and advanced automation systems.

3. Customization

Depending on your needs, you can customize frameless motors' torque output, shaft design, and winding configurations. This ensures the motor can be optimized for particular tasks and operational environments.

4. Reduced maintenance requirements

The integrated design of frameless torque motors generally requires lower maintenance than traditional motors. The lack of an external frame and fewer moving parts reduce mechanical wear and tear. These motors also feature advanced sealing and protection against contaminants.

The advantages of Mosrac's frameless motors

Mosrac's frameless motors come with several benefits.

-

1. Mosrac's frameless motors are lightweight and offer high power density. They also ensure precise control, which is essential for applications requiring accuracy.

-

2. Mosrac motor comes with an electromagnetic design. This can provide smooth motion while reducing energy consumption.

-

3. With a team of 20 skilled R&D, this company offers customized options from scratch for frameless motors. So, if you want a frameless motor for your specific application and brand, contact Mosrac's.

-

4. These motors can enhance heat dissipation with a cooling option. It increases motor lifespan. Along with this, their torque motors are designed to be maintenance-free. So you can minimize ongoing replacement costs.

-

5. You can easily install these motors without much effort. They operate quietly and reduce noise pollution. Also, their super torque output capacity delivers powerful torque for demanding tasks. You can use Mosrac motor for different robotic industries as they come with efficient components.

Conclusion

I hope now you know everything you need to choose the best torque motor for your robot joints. So, consider motor size, speed, and noise level, and inspect thermal resistance and prices based on your needs.

However, if you are still confused about choosing the best torque motor solution for your robot joints, contact the Mosrac expert team for suggestions.

FAQs

1. What type of motor should be used in a robotic arm?

There are several types of motors you can use for a robotic arm. For example, frameless torque motors have high torque and compact designs, which are best for advanced robotics. Meanwhile, servo motors are ideal for precise control and feedback capabilities.

2. What controls motor torque?

Motor torque is primarily controlled by adjusting the voltage or current. However, in DC motors, armature current directly influences torque. Meanwhile, AC motors use frequency control to regulate torque. Motor design parameters like the number of poles and magnetic field strength also impact torque output.

3. How does a frameless torque motor work?

A frameless torque motor has a rotor and a stator. The rotor is attached to the moving part, while the stator is fixed to the motor's structure. They generate magnetic fields that create rotational torque when currents pass through the motor's coils.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

Any questions or comments about Frameless Motors, Direct Drive Rotary Motors, and Encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!