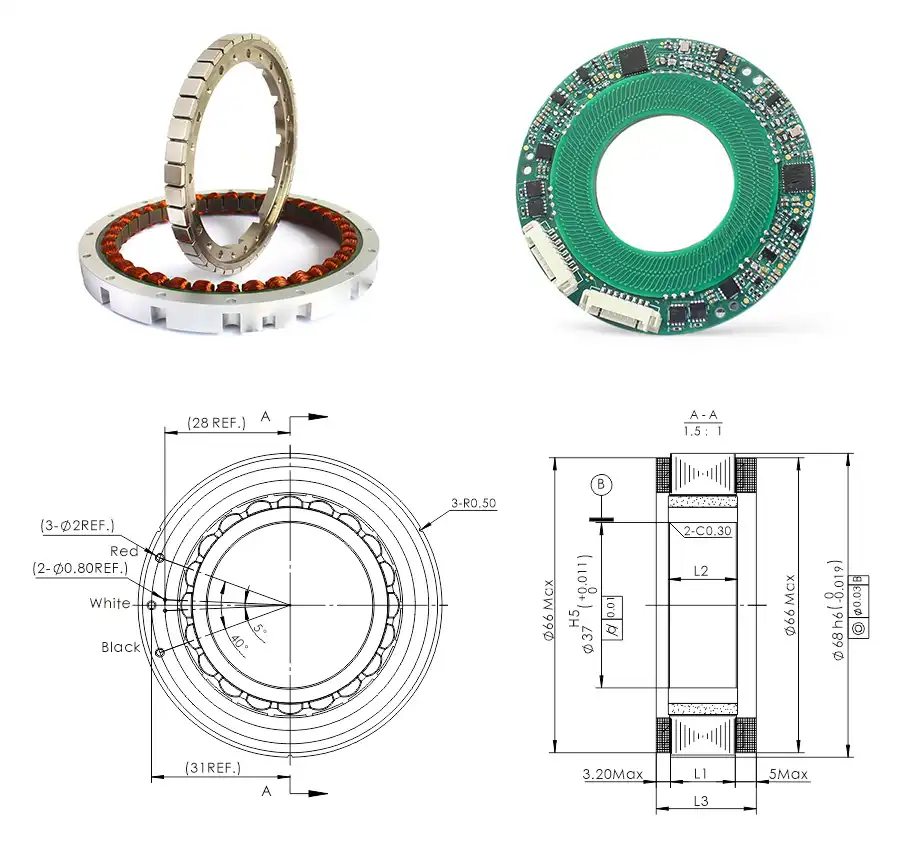

Mosrac U94 Frameless Inrunner Torque Motor

Frameless brushless DC (BLDC) motors are a non-conventional solution to many engineering challenges involving integrating motors into confined spaces requiring high-performance torque and completely customized shapes and sizes.

Frameless motors are motors working on electromagnetic induction and have similar magnets or windings and components to DC brushless motors. Still, a key difference makes frameless motors suitable for complex assemblies.

In this article, we’ll cover these differences, how a frameless motor works, the advantages of a frameless motor, and where you can use it.

What is a frameless motor?

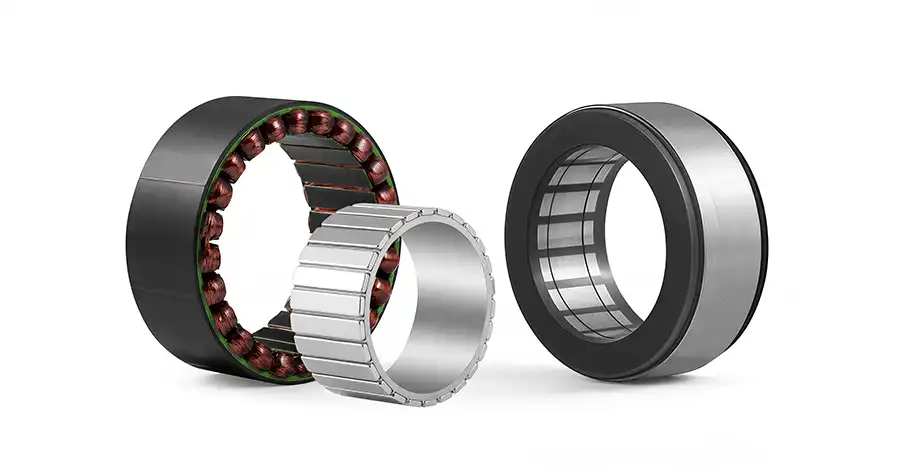

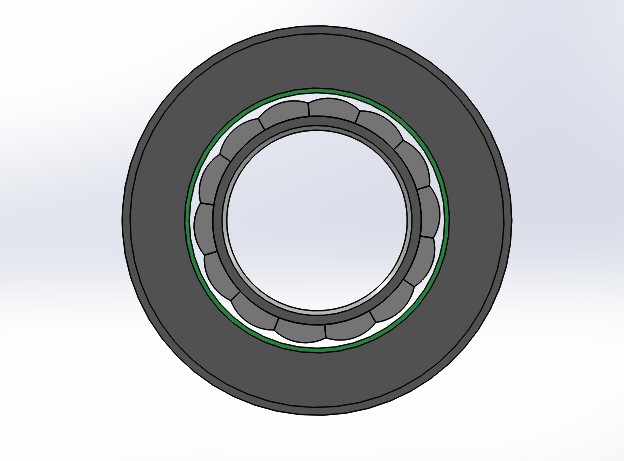

A Frameless motor has only two parts of an ordinary motor: the rotor and the stator.

1. Rotor:

The rotor is the rotating part of the frameless motor. It has permanent magnets mounted on the inside or outside (external rotors) interacting with the magnetic field produced by the stator causing it to spin.

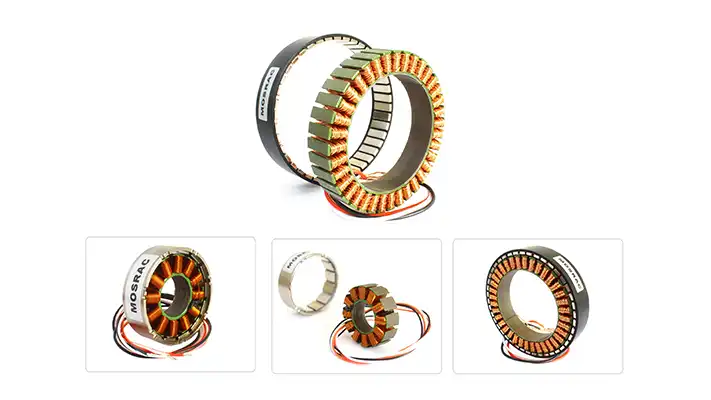

The stator with copper wire windings in the frameless motor

2. Stator:

The stator remains stationary in a motor. The stator holds the copper windings and is a core made of laminated steel sheets.

The rotor in the frameless motor based on different sizes

Components of a frameless motor

A direct-drive frameless motor is essentially made of a stator and rotor, but a frameless motor has many other components.

1. Bearings

Bearings are used with the rotor to allow smooth and friction-free mechanical motion.

2. Brushes

Brushes transfer the electrical current toward the rotor by physically contacting the commutator.

3. Commutator

The commutator is responsible for ensuring the alternating current is converted to direct current.

4. Hall effect sensor

Hall effect sensor can provide the location of the rotor to the controller by detecting magnetic field change and sending an analog signal to the controller.

It is an optional component for frameless brushless DC motors.

5. Temperature sensor

All motors come with operating conditions where the best performance can be achieved. Temperature sensors can provide internal temperatures to maintain the optimum conditions for the frameless motor.

6. Heat dissipation and cooling

All motors produce heat and a liquid or air cooling system can remove heat efficiently for extended torque usage.

The rotor can mount to any shaft for a desired function and such a bare assembly allows frameless motors to be used in applications where the size and shape of the motor housing need to be customized.

How does a frameless motor work?

A frameless motor is a direct drive torque motor that works on the same principle as any servo motor but usually has a larger diameter and applies torque to a shaft directly without any intervening mechanics.

Frameless motors are permanent magnet synchronous motors with toroidal winding construction and multipolar construction. The stator uses current provided from a source to create a magnetic field and the commutator creates a rotating magnetic field.

The interaction between the fixed magnets and a rotating magnetic field produces torque.

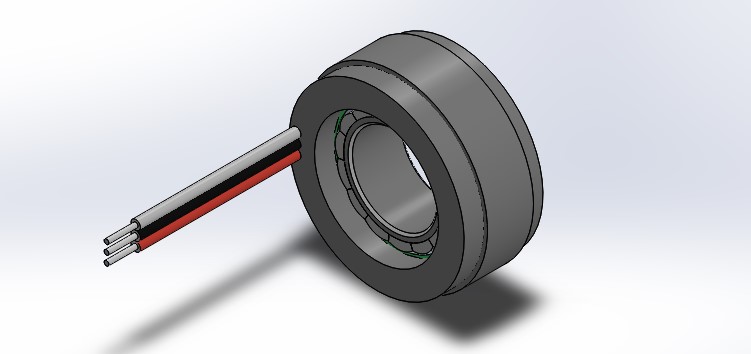

Frameless motors come with multiple leads. A typical frameless motor has:

1. Power lead

The power lead is used to supply voltage or current to the direct drive motor

2. Ground lead

The ground lead acts as the earthing connection necessary for the power and feedback leads.

3. Feedback lead

Feedback lead connects the direct drive torque motor to sensors and encoders like Data and hall effect sensors for position sensing.

4. Control lead

Control lead can be combined with feedback leads and transmit signals from the controller.

Frameless motor features (Benefits)

Frameless motors are racked with features the most important being the selection of a frameless direct drive torque motor isn’t based on power but peak torque and continuous torque.

1. Hollow shaft / bore

The frameless motor comes with a bore that allows the passage of wires and other components through the driven axis (center of the motor). This is impossible with a standard servo motor.

2. Customizable

Frameless motors can be designed for specific performance metrics instead of power ratings.

3. Easy maintenance

Frameless BLDC motor is made of a stator and rotor without any other components which leads to lower maintenance.

4. Customized windings

Frameless motors can have user-specific windings to match extremely performance-specific applications including custom voltage requirements, lamination variation for high-speed applications, and a choice of rare-earth magnetic materials.

5. Design

Mosrac offers complete design freedom with our efficient frameless motors. Our range of motor selection is suitable for a variety of uses owing to different diameters, windings, and mounting configurations.

Why should I use frameless motors?

Frameless brushless DC motors are mainly used because of their high customizability and sophisticated application.

Our frameless motors are picked for applications that require continuous and peak torque performance with direct integration into the assembly taking advantage of no intermediate power transmission components.

1. Compactness

Mosrac frameless torque motors start at just 25 mm in size making them suitable for any robotic or winding application requiring high torque from a small motor setup.

2. Direct drive

Frameless motors are called direct drive motors because the load connects directly with the motor without any shaft, gearing, or pulley. This reduces inaccuracies and compliance in torque applications.

3. High-torque delivery

Mosrac motors are optimized for the highest performance and have an electromagnetic design that delivers the best torque relative to the size and weight of the motor.

4. Thermal solution

For applications that require continuous torque delivery, the servomotor’s torque reduces over time due to heating. Frameless motors can provide the same performance for extended periods because of better heat dissipation.

5. Limited access

Frameless motors are ideal for high-end applications such as robotics that require constant operation and limited and rare maintenance.

Where can I use a frameless motor?

Frameless motors can be used in specialized applications and almost all servomotor applications.

✔ Robotics

Direct drive motors are particularly used in robotic joints that require precise positioning.

✔ Web winding

Web winding applications can benefit from direct drive motors for precise winding and unwinding.

✔ Wind turbines

Direct-drive wind turbines use frameless motors because of their precision control to adjust the blade pitch.

✔ Actuators

The most popular use of a frameless motor is any kind of actuation especially in robot arms and joints. Mosaic motors are particularly useful in rotary actuators and are used in many conveyor systems and indexing tables.

✔ Underwater robotic vehicles

Direct-drive motors are used in thrusters mounted on underwater exploration vehicles.

✔ Simulators and VR

Direct drive motors can provide instant and haptic feedback for simulation controllers and are used in many VR devices.

✔ Telescopes

Because of the elimination of housing and gears, direct drive motors have fast response times that telescopes need for real-time adjustment. Plus, these motors can provide continuous torque delivery during long observation sessions.

✔ Collaborative robots (cobots)

Cobots have many joints requiring multiple degrees of freedom of movement. Frameless motors are integrated into these joints due to their compactness and precise control.

Credit: Courtesy of Omron @The Application of Frameless Motors

✔ Surgical robotics

Surgical robots need extreme precision which cannot be delivered by induction motors. Direct drive motors can be easily fused with handheld or autonomous surgical robots.

✔ Mobile robots

Mobile robots have joint motors for the tilting, actuation, and rotation of different joints and linear motion. Frameless motors can be designed to fit the external housing of mobile robots and provide these functionalities.

✔ Humanoid robots

Humanoid robots have a design that cannot integrate standard servo motors. Mosrac frameless motors are used for limb actuation, joint control, and complete rotation with precise feedback.

Courtesy of DMKE Gear

✔ Exoskeleton

An exoskeleton is a wearable mechanical device aiding people in carrying heavier loads or assisting physical rehabilitation. Essentially, it acts as an extension of the skeleton and has identical joints to a skeleton. These joints use frameless motors of various sizes and torque intensity for real haptic feedback.

✔ SCARA robots

SCARA robots have at least three tilting joints, each of these joints needs a motor with a different diameter. The shaft joint uses a smaller motor than the base joint. Such joints require completely customized frameless motors and on-demand manufacturing.

✔ Military robotics

Military applications like ACPs, unmanned vehicles, and turrets all use frameless motors for quick and precise targeting.

✔ Semiconductor

Frameless motors are used in vacuum robots inside wafer-handling robots to position the wafers.

✔ Consumer electronics

Consumer electronics are manufactured using pick-and-place robots. These robots are tasked with accurately placing components inside electronics. Frameless motors are compact and many robots can be placed closely together in a small space using Frameless motors.

✔ Machine tools

Almost any tool with a rotating spindle can employ a frameless motor for high and continuous torque.

✔ Medical

Medical applications require limited noise and disturbances. Frameless motors do not have any gears and intermediate assembly which makes them silent for patient comfort. They are used in MRI scanners, CT scanners and other diagnosis equipment.

✔ Printing

Frameless motors are used with many printer heads for their precision.

✔ Aerospace

Housed direct drive motors are used in flight system control actuators to provide axial movement and actuating control surfaces.

✔ Vehicles

Frameless motors are increasingly being used in drive systems of electric vehicles for energy efficiency and direct torque delivery.

View our Mosrac's frameless torque motors

The U-series frameless stator-rotor kits represent Mosrac's consistent evolution of the previous generation's frameless series. Delivering excellent overload capabilities, high torque density, and maximum precision, these kits are built to fit seamlessly into compact spaces. They are widely used for demanding applications such as medical technology, robotics, mechanical engineering, and tools, etc.

Inrunner Frameless Motor

The inrunner frameless motor offers a compact, well-balanced design suitable for high-speed, precision motion. Low rotor inertia enables quick acceleration, smooth torque delivery, and steady performance.

We will always combine service quality with integrity. We will launch new frameless motors with excellent services and expertise,

providing customers with the most satisfying production, operation, export, and shipping services.

Outrunner Frameless Motor

The outrunner frameless motor has a rotor that surrounds the stator, providing higher torque density at lower speeds. Its larger rotor diameter offers an excellent torque-to-weight ratio for direct-drive systems.

Frameless motor vs housed motor

Housed Direct Drive Motors (DDR motors) are torque motors with an enclosed housing. There are no shafts, gears, or pulleys to transfer the mechanical rotation but the stator and rotor are housed in a motor unit. This provides an extra layer of protection while still providing the functionality of a direct drive motor.

Mosrac frameless motor vs housed torque motor

Mosrac's housed motors like the FE and FL series start at an outer diameter of just 40 mm and are more cost-effective than our frameless motors because of off-the-shelf standard sizes. Our frameless motors can be completely sized and customized for your specialized applications and require less maintenance than housed motors.

Frameless motor vs servo motor

Standard servomotors come with stators, rotors, bearings, shafts, and housing. Servomotors are sold as a complete package and have standard applications. Frameless or direct drive motor is a type of servo motor that comes with a stator and rotor designed to be integrated directly into its application.

Frameless motor vs induction motor

Induction motors are not as precise as frameless motors and are not use for high-performance applications. They work using a rotating magnetic field and are less efficient than frameless motors but are more robust. Induction motors deliver lower torques than direct drive motors and come in standard sizes.

Frameless motor advantages

Mosrac frameless motors are suitable for high-performance applications and offer numerous advantages.

● Customizable design to suit your project. Our engineers can work from scratch to build a frameless motor with the windings and dimensions suitable for your assembly.

● All frameless motors have an optimized electromagnetic design.

● The frameless motor has a relatively small weight for its torque density.

● Direct integration of Mosrac motors into your device improves heat dissipation and allows for customized cooling solutions.

● Our housed DDR motors and frameless motors are both lower maintenance than standard servo motors and induction motors.

● Mosrac frameless motors have been used in leading robotics and energy industries for efficient and reliable equipment.

● Frameless motors have minimal backlash because they use no gearing.

Conclusion

Direct drive motors are named after their direct torque delivery system that does not require any intermediate component like a shaft. This separates frameless motors from standard servo motors and gives this class of motors a specialized market.

They are mostly used in robotic arms, MR scans medical equipment, and applications requiring high torque delivery in a custom assembly. DDR Brushless DC motors are lightweight, have a higher torque density, and run on lower maintenance. Direct Drive motor can also have a housing but it will always use a mechanical torque transmission system like a pulley or shaft.

The case of a customized frameless torque motor

Mosrac has a legacy of delivering high-performance, reliable, and high-density torque motors that can be customized through our team of skilled engineers. We offer customization from windings and material selection to dimensions of the rotors.

We have a selection of frameless direct-drive torque motors that fit common assemblies easily. You can easily select one of our frameless motor solutions using our comparison chart.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

Any questions or comments about frameless motors, direct drive rotary motors, and encoders? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!