So, are you confused about choosing between frameless and brushless motors? Don’t worry! I am here to help you with my 20 years of experience working in the motor industry.

Both motors have specific features, such as frameless motors that come with a high torque density. Meanwhile, brushless motors provide excellent durability and longer operational lifetimes.

In this article, I will explore the benefits and applications of frameless motors and brushless motors, offering insight into which one is right for you.

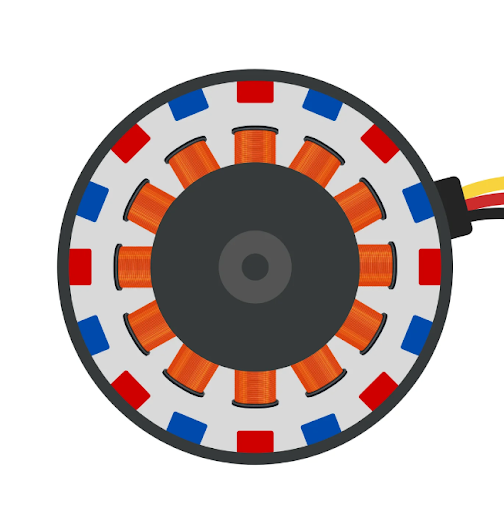

What Is Frameless Motors?

Photo Credit: www.pranshu.com

Frameless motors represent a cutting-edge approach to electric motor design, where the rotor and stator are decoupled from a traditional housing structure. This innovative configuration allows for greater flexibility in integration, enabling manufacturers to use them in diverse applications, from robotics to electronic vehicles.

By eliminating the bulk of a frame, these motors can be custom-fitted into compact spaces or integrated directly into machines. This way, they enhance overall efficiency and reduce weight.

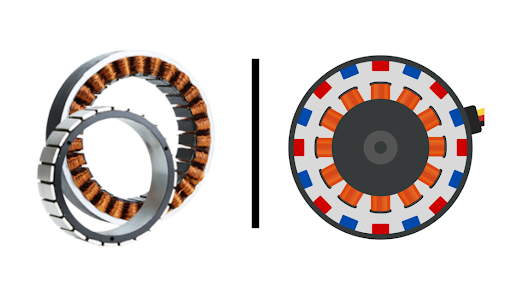

What Is Brushless Motors?

Photo Credit: www.tytorobotics.com

A brushless motor is an electric motor that operates without the traditional brushes. This technology relies instead on electronic controllers to switch the current through the windings. This resulted in significant efficiency improvements and reduced maintenance needs.

Therefore, the absence of brushes eliminates friction and wear, leading to a longer lifespan and quieter operation. These are ideal attributes for applications ranging from drones to electric vehicles.

Quick Chart Frameless VS. Brushless Motors

| Difference | Frameless Motor | Brushless Motor |

| Design | The rotor & stator only, need custom housing. | Complete motor with housing, bearings, and shaft. |

| Performance | Highly tailored for high torque and efficiency. | High efficiency but less customizable. |

| Application | Aerospace, robotics, medical devices, and industrial automation. | Drones, RC vehicles, electric bikes, fans. |

| Cost | Higher due to customization and integration. | Lower upfront, no integration needed. |

| Maintenance | Dependent on system design and components. | Low maintenance, self-contained design. |

What Are The Differences Between Frameless Motor VS Brushless Motor?

Photo Credit: Pranshu and Tytorobotics

Frameless motor and brushless motor has many distinctions. I have included here some of the most common differences. Let’s take a look at them.

1. Design

A frameless motor consists only of the rotor and stator, without the housing, bearings, or shaft. This means it is designed to be integrated directly into the mechanical assembly of the system. This motor provides flexibility for custom designs.

On the other hand, a typical brushless motor includes the rotor, stator, and housing, along with bearings and a shaft. The motor comes as a complete unit, ready for use in various applications without needing additional components for assembly.

2. Customization

Frameless motors are highly customization and more flexible. Therefore, you can integrate it into a specific mechanical system, adjusting the form factor torque.

While there are different variants of brushless motors available, the degree of customization is lower than that of frameless motors. However, brushless motors still offer a range of sizes, speeds, and power ratings for various general applications.

3. Speed

Frameless motors can be designed for either high-speed or low-speed operation, depending on the specific requirements of the system. Where high torque is needed, such as robotics and machinery, frameless motors might run at lower speeds. When integrated into systems requiring fast motion, such as medical devices and aerospace, frameless motors can achieve speeds of up to 20,000 RPM or higher.

However, brushless motors are known for high-speed capabilities, especially in applications like drones or electric vehicles. Their speeds are usually easier to predict and control due to their self-contained design.

4. Torque

Frameless motors are designed to deliver higher torque relative to their size due to the custom nature of the design. The torque characteristics are usually highly optimized based on the specific mechanical integration.

In contrast, brushless motors can also deliver good torque; their torque density isn’t as high as frameless motors. However, they are still highly efficient and reliable for applications requiring continuous torque output.

5. Efficiency

Frameless motors offer greater efficiency because they can be customized and integrated into a system with minimal losses. However, brushless motors are also highly efficient due to their lack of brushes. This eliminates friction and reduces energy loss.

6. Noise

Frameless motors come with low noise levels depending on how they are integrated into the system. If you need motors for the hospital, you should choose frameless motors. In comparison, brushless motors are quieter than many traditional motor types, but they are not as quiet as frameless motors.

7. Application

If you need specific form factors, high torque to weight ratios, and precision, where you can use frameless motors. Their common applications are:

▪︎ Electric consumer

▪︎ Robotics Application

▪︎ Medical Devices

▪︎ Industrial automation

▪︎ Photoelectric turntable

On the other hand, for reliability and efficiency, you can use brushless motors. They are widely used in applications:

▪︎ Drones

▪︎ RC Vehicles

▪︎ Industrial Automation

▪︎ Consumer Electric

8. Cost

The cost of frameless motors is usually higher due to the customization involved. On the contrary, brushless motors are generally less expensive than frameless motors. They are mass-produced and widely available in standardized designs.

9. Maintenance

Frameless motor maintenance requirements depend on how the motor is integrated into the larger system. Bearings, cooling systems, and mechanical structures must be serviced as part of the overall machine maintenance. Conversely, brushless motors have low maintenance because there are no brushes to wear out.

Which Motor Is Better For You: Frameless Vs Brushless

When deciding between a frameless motor and a brushless motor, the right choice largely depends on your specific application:

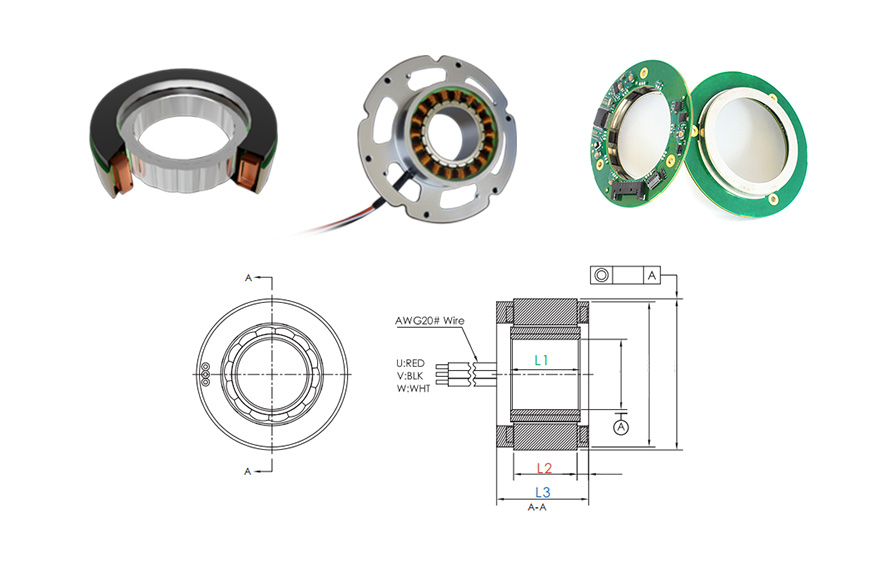

When To Choose Frameless Motor?

Photo Credit: Mosrac motors

▪︎ If you need a compact, lightweight design.

▪︎ When your application requires high torque and precise control.

▪︎ Customization and integration into an existing system are important.

▪︎ Space-saving is a priority.

When To Choose Brushless Motor?

▪︎ You need an efficient, low-maintenance motor.

▪︎ Longevity and reliability are critical to your application.

▪︎ You require advanced speed and position control.

▪︎ You're working with applications like drones, EVs, or industrial systems.

Looking for a custom solution?

Tell us about your requirements and our application engineers will help you find the right solution today!

FAQs

1. Are brushless motors more efficient than frameless motors?

In general applications, brushless motors tend to be more efficient due to their design, which minimizes energy loss. However, efficiency can vary based on specific use cases and designs.

2. Can I use a frameless motor as a brushless motor?

Yes, a frameless motor can function as a brushless motor since it typically uses the same technology. But before that, compatibility with your application should be verified.

3. Which type of motor is more suitable for high speed applications?

Brushless DC motors are typically the most suitable for high-speed applications due to their efficiency and ability to maintain high RPMs.

4. How does a brushless motor differ from frameless motors?

Both types use magnetic fields to create motion. But frameless motors typically lack an outer casing, relying on external structures for support and alignment.

Conclusion

The choice between frameless motors and brushless motors largely depends on your specific application needs and performance expectations.

However, Mosrac offers different types of motors for various types of customer needs. Our commitment to customization ensures that clients can tailor solutions that align perfectly with specific applications, enhancing performance and efficiency. So see our products and contact us now.

Any questions or comments about Frameless Motors & Direct Drive Rotary Motors? Contact us at sales12@mosrac.com for sales, technical inquiries, or order samples online today!