Introduction

Brushless DC motors are a game-changing solution for countless engineering challenges, offering high performance, energy efficiency, and precise control in a compact design. Unlike traditional DC motors, BLDC motors operate without brushes, relying on electronic commutation and advanced electromagnetic principles. This makes them highly durable, energy-efficient, and indispensable across a wide range of industries.

In this article, we’ll explore what is a BLDC motor, how they work, the advantages they offer, the types available and where they are most commonly used.

Still, curious about, what is a BLDC motor? Let’s explore the power behind BLDC motors, with insights into some of the most advanced product solutions and innovations.

Understanding BLDC Motors

A Brushless DC Motor (BLDC) is a synchronous motor that uses electronic commutation instead of mechanical brushes to control the current flow. It consists of a permanent magnet rotor and a stator with windings. The absence of brushes eliminates wear and sparks, making it ideal for high-performance applications requiring reliability and efficiency.

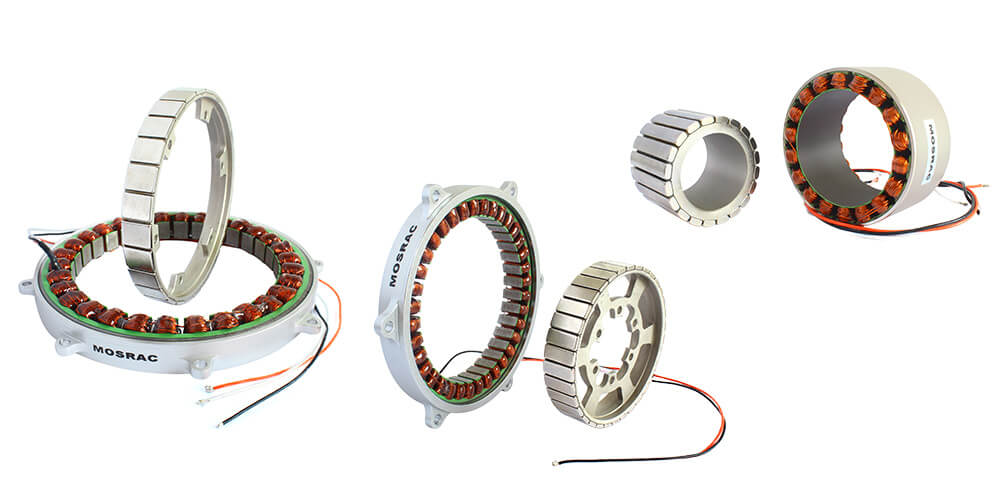

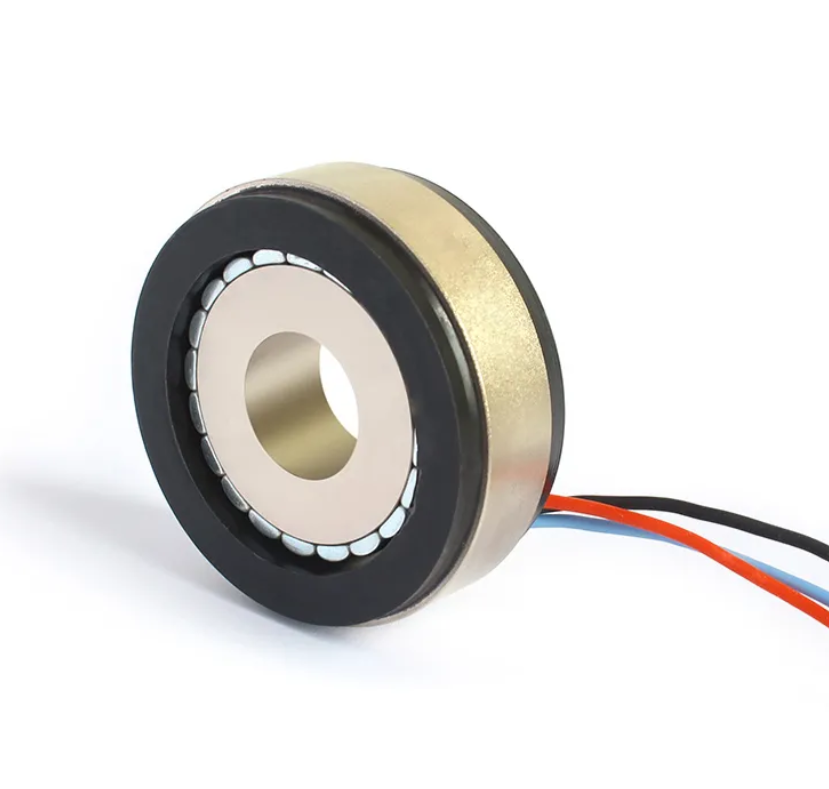

Mosrac’s newly launched Frameless DC Motors

BLDC motors are known for their high torque-to-weight ratio, efficiency, and precision. Their low maintenance requirements and ability to operate at variable speeds make them highly adaptable for industries like robotics, industrial automation, and consumer electronics. Key benefits include reduced energy consumption, long lifespan, and minimal electromagnetic interference.

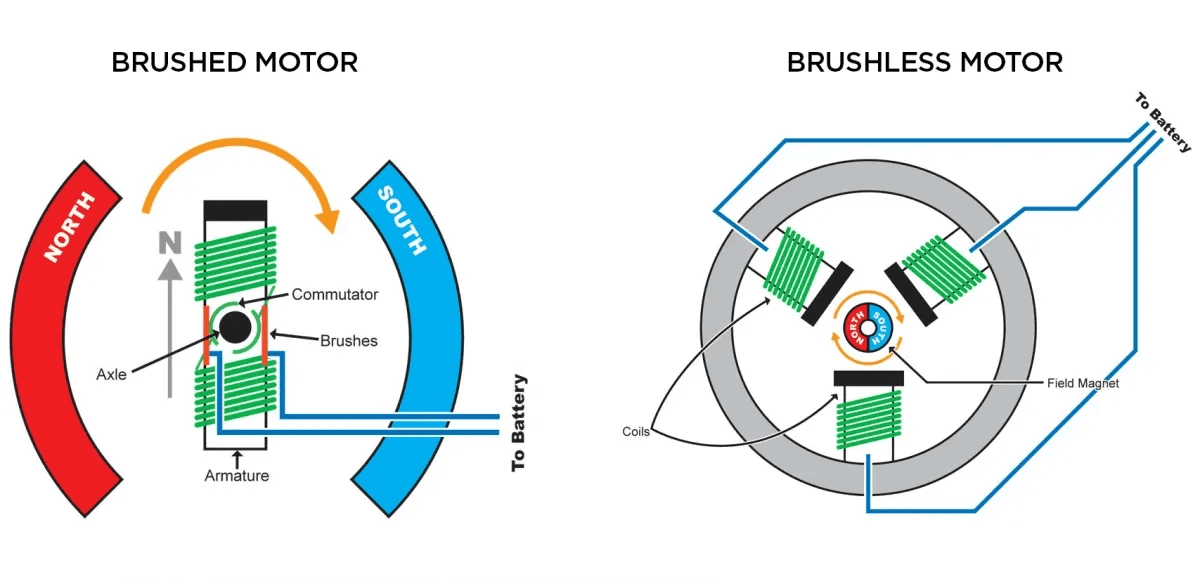

Unlike brushed DC motors, BLDC motors lack brushes and commutators, reducing friction and energy loss. This design increases efficiency and enables quiet operation and higher speed ranges. While brushed motors are cost-effective for basic applications, BLDC motors dominate where performance and durability are critical.

BLDC motor has the following key components:

▪︎ Rotor: The rotor is the rotating part of a BLDC motor. It houses permanent magnets that rotate with the motor shaft.

▪︎ Stator: The stator remains stationary in a motor. It contains windings that generate a rotating magnetic field.

▪︎ Hall Sensors: These sensors detect rotor position to ensure accurate electronic commutation, enabling smooth and precise motor operation.

These components work together to deliver superior performance, flexibility, and efficiency, allowing BLDC motors to power a wide range of cutting-edge applications.

How Does a BLDC Motor Work?

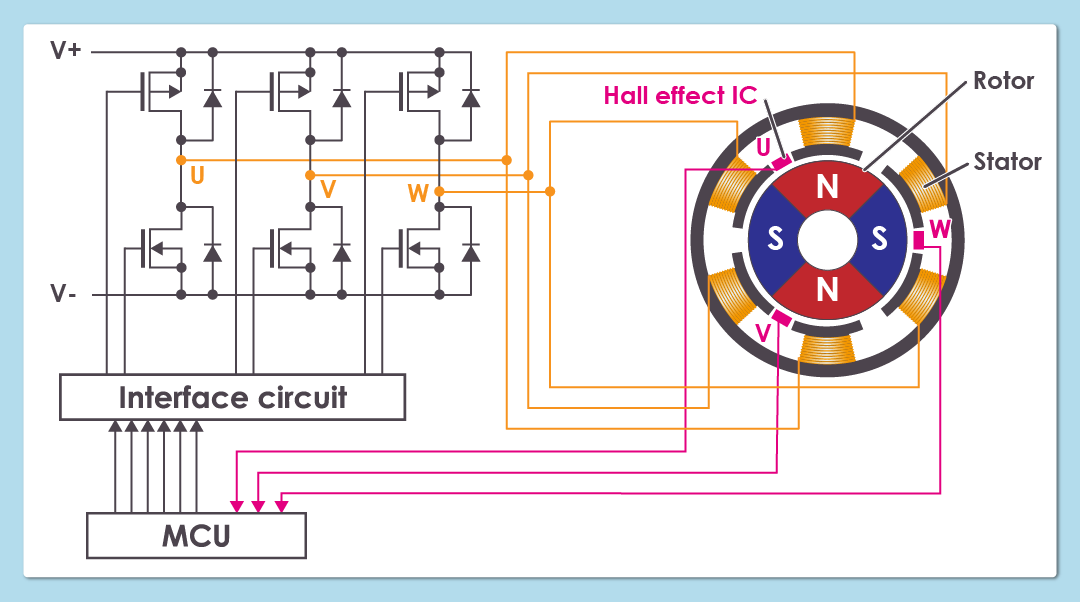

The BLDC motor operates electronically, commutating the current in its stator windings to create a rotating magnetic field. This field interacts with the permanent magnets on the rotor, causing it to spin. Sensors, such as Hall-effect sensors or sensorless techniques, are used to determine the position of the rotor and control the switching of currents in the stator windings. The process ensures synchronized motion and maximizes torque output.

Schematic Structure of a BLDC Motor; Source: ABLIC

Unlike traditional DC motors, which rely on mechanical brushes and a commutator to switch current, BLDC motors use electronic commutation. A motor controller governs this process by analyzing rotor position data and sending precise electrical signals to the stator windings. This approach eliminates the mechanical limitations of brushes and enables smooth operation, especially at high speeds.

Below are the advantages of no mechanical brushes:

▪︎ Reduced Wear and Tear: The absence of brushes minimizes friction and wear, resulting in significantly longer motor life and reduced maintenance requirements.

▪︎ Increased Efficiency: BLDC motors achieve superior efficiency because no energy is lost due to brush friction. This makes them ideal for applications demanding low energy consumption and extended operational periods.

This advanced design allows BLDC motors to outperform their brushed counterparts in precision, durability, and energy efficiency, making them useful in modern technologies.

Types of BLDC Motors

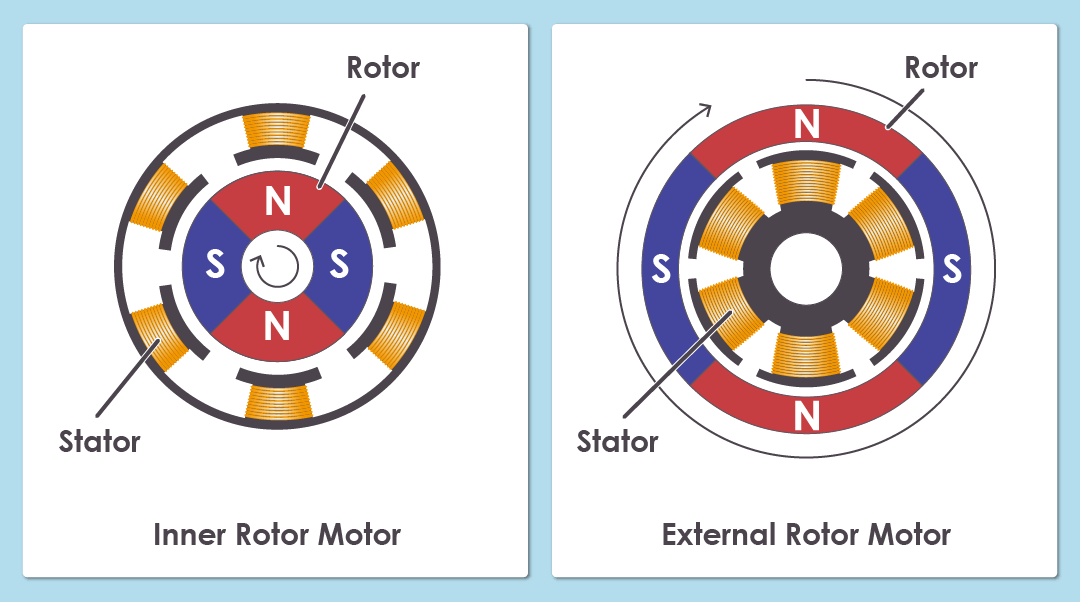

Inner vs. Outer Rotor Designs

Schematic Control Diagram of a BLDC Motor; Credits: ABLIC

▪︎ Inner-Rotor Motors: The rotor is located inside the stator. This compact design offers high rotational speeds and greater thermal management. These motors are widely used in applications such as robotics, drones, and industrial machinery.

▪︎ Outer Rotor Motors: Here, the rotor surrounds the stator. This design provides higher torque due to the increased moment of inertia, making it suitable for electric bicycles, HVAC systems, and other low-speed, high-torque applications.

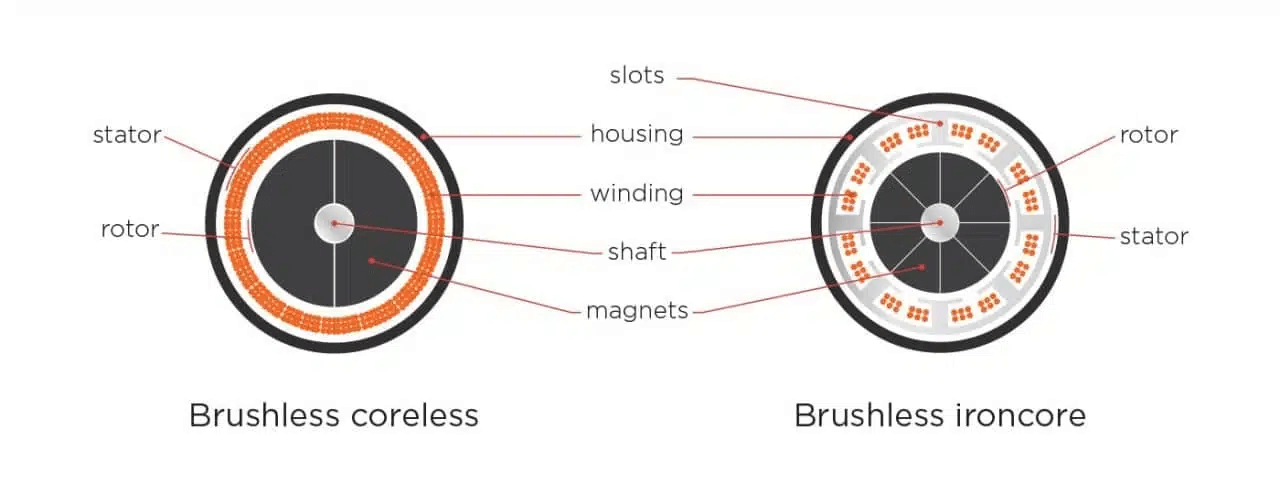

Iron Core vs. Ironless Core

Iron Core vs. Ironless Core; Source: servotecnica

▪︎ Iron Core Motors: The stator windings are wound around an iron core, enhancing magnetic flux and providing higher torque. These motors are commonly used in power-intensive applications like electric vehicles and industrial automation.

▪︎ Ironless Core Motors: These motors have stator windings embedded in a non-magnetic core, eliminating cogging and offering smoother operation. They are preferred for precision applications such as medical devices and aerospace systems.

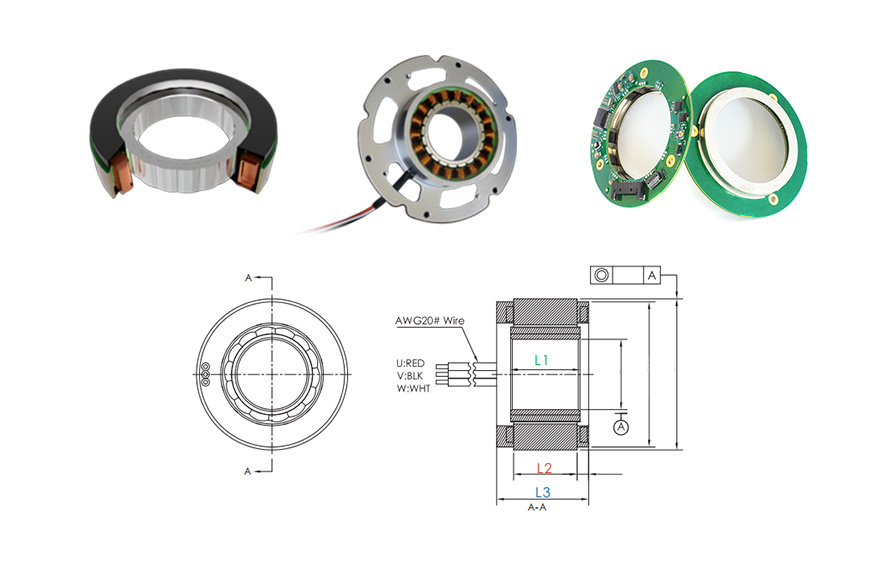

Frameless Torque Motors

U60 Series Frameless BLDC Motor

Frameless BLDC motors consist of separate rotor and stator components without a housing. This modular design allows seamless integration into systems like robotics and automation, where space and weight are critical factors. A 60mm OD frameless torque motor can directly drive robot joints with optional rated torque.

Housed Torque Motors

FI-224 Series Housed Direct Drive Rotary Motor

FI-7556 - Mosrac new series of DD motor

Housed BLDC motors include an enclosed frame, providing protection from external elements and ease of installation. The FI-224 series is a Housed Inner-rotor Torque Motor, also known as a direct drive rotary (DDR) motor. It can be used in applications such as rotary table motors. The rated torque options are 9.9Nm and 30Nm, with motor speed ranging from 150 rpm to 250rpm.

Specifications and Features of BLDC Motors

When selecting a Brushless DC Motor (BLDC), understanding technical specifications and application-specific features is critical.

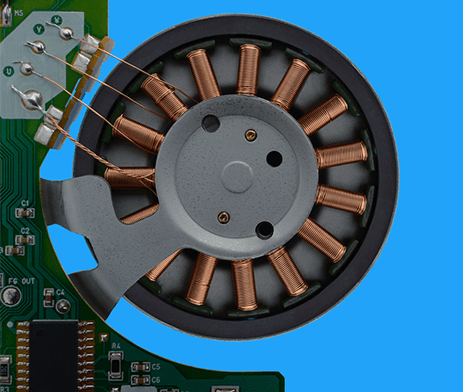

Small Brushless DC Motor Coils on Plate

At Mosrac, we offer a wide range of BLDC motors designed to cater to various industries. Pricing depends on specifications such as power, torque, and additional customization requirements. Our high-quality motors ensure optimal performance with competitive pricing for standard and custom solutions.

Power Ratings

▪︎ Low-Power Motors: Ideal for consumer-grade applications like small appliances, drones, and robotics, with power ratings typically below 100W.

▪︎ High-Power Motors: Suited for industrial applications such as electric vehicles, HVAC systems, and heavy machinery, with power ratings exceeding 1kW.

Application-Specific Designs

▪︎ Industrial-Grade Motors: Durable and robust for automation, robotics, and high-precision tasks.

▪︎ Consumer-Grade Motors: Lightweight and efficient for appliances, fans, and personal mobility solutions.

Design Specifics

▪︎ Ironless Core Motors: Cogging-free operation for medical and precision equipment.

▪︎ Iron Core Motors: High torque and efficiency for power-demanding applications.

▪︎ Frameless Motors: Compact and modular for robotics and custom integrations.

▪︎ Housed Motors: Enclosed designs for protection in harsh environments.

Key Specifications

▪︎ Torque: From 0.1 Nm to 10+ Nm, depending on application requirements.

▪︎ Speed: Adjustable from 100 RPM to 10,000+ RPM.

▪︎ Power: Ranges from 10W to 10kW.

▪︎ Dimensions: Customizable to fit specific use cases, ensuring easy integration.

Explore our product catalog to find the perfect BLDC motor for your application, backed by innovative design and unmatched performance.

Applications of BLDC Motors

Brushless DC (BLDC) motors are widely used across industries due to their efficiency, reliability, and adaptability. Below are real-world examples and industry-specific applications where BLDC motors excel.

Robotics

MOSRAC Frameless Torque Motor for Robot Applications

From industrial automation to medical robots, BLDC motors power actuators and joints requiring precise movements and low maintenance. Mosrac U38 series, and U50 series frameless motors are widely used in collaborative robots (cobots) and high-precision robotic arms. These motors provide a very compact design, excellent precision, better overload capacity, high torque density, and lightweight.

Electric Vehicles (EVs)

BLDC motors are the backbone of EV propulsion systems, delivering high torque, efficiency, and silent operation. They are used in both passenger cars and electric bikes. For example, Mosrac U60 series high-power motors provide exceptional performance in EV drivetrains, ensuring energy efficiency and extended range.

Drones

Lightweight and compact BLDC motors are ideal for drones, providing precise speed control and long operational lifespans. Direct Drive Rotary Motors excels at maneuvering camera gimbals, servos, and flight control surfaces with millisecond shifts critical for stable autonomous flight. The DDR motors manufactured by Mosrac include the FE series and FI series, with various size options, specifically designed for drone integration, the OD ranges from 40mm to 375mm.

Consumer Electronics

Small, efficient BLDC motors drive fans, washing machines, and refrigerators, offering durability and minimal power consumption. Mosrac UE Series Outrunner Frameless DD Torque Motors provide smooth operation, making them perfect for sensitive home appliances. The continuous torque values span from 0.01Nm to 6Nm, and voltage ranges from 12,16, 24, 36, and up to 48V or custom.

Visit Mosrac to explore our product lineup tailored for these industries and more!

BLDC Motors vs. Brushed DC Motors

BLDC Motors vs. Brushed DC Motors; Credits: haredataelectronics

Let’s talk about some common factors that will influence the efficiency of the brushed and brushless motor, and help you choose the right motor for your application!

Operating Speed

▪︎ BLDC Motors: High efficiency due to electronic commutation, minimizing energy loss and maximizing torque output. BLDC motors are optimized for peak energy efficiency, making them ideal for EVs and industrial applications.

▪︎ Brushed DC Motors: Brushed motors work best at speeds between 1,000 and 10,000 RPM. Lower efficiency as mechanical brushes create friction and energy loss, particularly at high speeds. U130 Series Frameless Servo Motors ensure high performance in various challenging environments.

Torque Stability

▪︎ BLDC Motors: Superior performance, offering higher speed ranges, precise control, and smoother operation. U38 Series Frameless Torque Motor ensures stable torque and precise speed control. The rated torque options range from 0.025Nm to 0.075Nm.

▪︎ Brushed DC Motors: Performance is limited by the mechanical commutator and brushes, with reduced efficiency at higher speeds and loads. Brushed motors can only achieve maximum torque at specific points during their rotation. These motors have lower torque capabilities and higher torque ripple, which in some cases causes vibration and noise due to the applications.

Maintenance

▪︎ BLDC Motors: Require minimal maintenance due to the absence of brushes, resulting in longer operational life, often exceeding 10,000 runtime hours. Our products are engineered to handle demanding environments with minimal downtime.

▪︎ Brushed DC Motors: Regular maintenance is required to replace brushes, which wear out over time and increase operational costs. This limits their lifespan to around 2,000 to 5,000 hours.

Cost

▪︎ BLDC Motors: Higher initial cost due to complex controllers and advanced materials. However, the reduced energy consumption and maintenance costs make them more cost-effective over their lifecycle.

▪︎ Brushed DC Motors: Lower upfront cost, suitable for budget-constrained projects or short-term applications. These motors are becoming popular, especially in the automotive industry, and technology is improving.

While brushed DC motors serve basic applications, BLDC motors outperform in efficiency, longevity, and performance. Explore these cutting-edge BLDC motor solutions to unlock unmatched reliability and energy savings for your next project.

Recommended Reading: Brushless Vs Brushed Motors: Explained for Beginner To Advanced Users

Challenges in Using BLDC Motors

BLDC motors are more expensive upfront compared to brushed DC motors due to their advanced design and the need for electronic controllers. However, the higher initial investment is offset by their efficiency, longer lifespan, and minimal maintenance requirements. The BLDC U200 Series BLDC motor is designed with cost-efficiency in mind, delivering long-term savings through superior energy performance and durability.

BLDC U200 Series BLDC Motor

The operation of BLDC motors relies on sophisticated controllers to manage electronic commutation and rotor positioning. This complexity can pose a challenge for integration in simple systems. The U60 60MM Series BLDC Motor is a highly customized solution, ensuring seamless integration and precise control with various options to meet your specific needs.

The high-speed switching of electronic controllers in BLDC motors can generate electromagnetic interference, potentially disrupting nearby electronic devices. Our products incorporate advanced shielding and noise suppression technologies, ensuring EMI compliance with global standards and making them suitable for sensitive environments.

Recommended Reading: How to Choose the Right Torque Motor: 14 Essential Criteria

Future Trends in BLDC Motor Technology

The evolution of Brushless DC (BLDC) motors continues to reshape industries, with cutting-edge innovations driving enhanced performance and expanded applications.

Brushless Motor in Quadcopter Blades

Modern BLDC motors are advancing with compact designs, higher torque densities, and improved thermal management. Innovations such as frameless and ironless core motors enable greater flexibility for integration into specialized systems like robotics and medical devices.

Integrating BLDC motors with IoT and smart systems transforms automation and energy efficiency. Smart controllers with real-time monitoring and adaptive algorithms enable precise motor control, predictive maintenance, and improved energy management.

BLDC motors play a critical role in renewable energy systems, powering wind turbines, solar trackers, and electric vehicles. Their high efficiency and reliability align perfectly with the growing demand for sustainable technologies.

Curious about how it’s going to be? Mosrac is committed to being at the forefront of innovation, ready to help customers choose the appropriate torque motor for different applications. Consider it your premier destination for custom torque motors with exceptional services!

Conclusion

BLDC motors are revolutionizing industries with their high efficiency, durability, and precision. Compared to traditional brushed motors, they offer significant advantages, including reduced maintenance, superior performance, and energy savings. From electric vehicles to robotics and consumer electronics, their versatility makes them essential for modern applications.

At Mosrac, we provide advanced BLDC motor solutions tailored to your specific needs, combining innovative designs with reliable performance. Whether you require standard models or custom solutions, our products are engineered to exceed expectations. Explore our comprehensive range at Mosrac and find the perfect motor for your next project!

Frequently Asked Questions

1. What is a BLDC motor?

A BLDC motor is a brushless DC motor that uses electronic commutation for efficiency, durability, and precise control, making it ideal for modern applications.

2. How does a BLDC motor work?

A BLDC motor operates via electronic commutation, synchronizing the stator's magnetic field with the rotor's position for smooth, efficient, and high-performance operation.

3. What are the benefits of BLDC motors over brushed motors?

BLDC motors offer higher efficiency, longer lifespan, reduced maintenance, and quieter operation; they outperform brushed motors in performance and reliability across diverse applications

4. Where are BLDC motors commonly used?

BLDC motors are used in electric vehicles, drones, robotics, HVAC systems, and consumer electronics for their efficiency, precision, and low maintenance.

Looking for a Custom Solution?

Tell Us about your requirements, and our application engineers will help you find the right solution today!