Outrunner Frameless Direct Drive Torque MotorHigh positioning accuracy, various sizes, low weight, optimal speed control

Continuous torque values span from 0.01Nm to 6Nm and voltage ranges from 12,16, 24, 36and up to 48V or custom.

These motors are available in outer diameters of 14.9mm (0 587"), 22mm (0.866”), 49mm(1.929"), and reaching up to 485mm (4.291"), or custom.

Comparison Table of Outrunner Frameless Torque Motor

Outrunner frameless torque motors manufactured by Mosrac are specially designed for various demanding applications such as robots, machine tools, etc. with various options of sizes, speeds, weights, and power to perfectly match your facility spacing & industry needs.

| Model | OD(mm) | ID(mm) | HeightL(mm) | Rated Torgue(N.m) | Rated Current(A) | Rated speed(rpm) | Voltage(v) | Weight(kg) | |||||||||

| UE1406 | 14.9 | 5 | 6.25 | 0.01 | 0.59 | 850 | 12 | 0.004 | |||||||||

| UE2208 | 22 | 9 | 8.5 | 0.03 | 0.66 | 800 | 12 | 0.012 | |||||||||

| UE2506 | 25.3 | 10 | 6.2 | 0.04 | 0.66 | 792 | 12 | 0.012 | |||||||||

| UE3306 | 33.4 | 14 | 6.2 | 0.06 | 0.81 | 950 | 12 | 0.022 | |||||||||

| UE4009 | 40 | 22 | 9.5 | 0.07 | 0.79 | 1325 | 12 | 0.024/0.032 | |||||||||

| UE4013 | 40 | 22 | 13.7 | 0.11 | 0.53 | 363 | 12 | 0.036/0.047 | |||||||||

| UE4913 | 49 | 25 | 13.5 | 0.21 | 0.79 | 343 | 16 | 0.078 | |||||||||

| UE4918 | 49 | 25 | 18.5 | 0.28 | 0.59 | 238 | 16 | 0.11 | |||||||||

| UE5819 | 58.6 | 24 | 19 | 0.76 | 1.12 | 221 | 24 | 0.167 | |||||||||

| UE5829 | 58.6 | 24 | 29 | 1.26 | 1.28 | 221 | 24 | 0.281 | |||||||||

| UE6815 | 68 | 36 | 15.5 | 0.73 | 1.19 | 182 | 24 | 0.156 | |||||||||

| UE6830 | 68 | 35.5 | 30.5 | 1.77 | 7.4 | 504 | 36 | 0.345 | |||||||||

| UE9014 | 90 | 58.5 | 14 | 1.6 | 1.75 | 130 | 24 | 0.206 | |||||||||

| UE9019 | 90 | 58.5 | 19 | 2.16 | 17 | 1800 | 24~48 | 0.313 | |||||||||

| UE10933 | 109 | 78 | 33 | 6 | 4 | 140 | 24 | 0.576 |

Case studies (Customized frameless motors developed with our clients)

Part no. description

Torque Motor Series

U: Frameless torque motor

F: Housed Torque motor

Standard: 200mm,Customizable

eg:DC24V, AC 220V

None: Standard

C: Customized

B: With band brake

None: Without band brake

H: with Hall

no H:without Hall

E: Photoelectric incremental (analog)

E1: Photoelectric incremental type (digital)

E2: Photoelectric absolute type

E3: Magnetoelectric type

for example: 0.2Nm, 3Nm, 20Nm, 200Nm

for example: 25mm, 115mm

for example: 10.8mm, 30.8mm

I: inner rotor

E: outer rotor

eg:

UI:inner rotor frameless motor

UE:outer rotor frameless motor

FI:inner rotor DD motor

FE:outer rotor DD motor

Specification

| Insulation level | Grade F |

| Insulation withstand voltage | AC1500 V 60s |

| Insulation resistance | 10MΩ or more DC500V |

| Excitation method | three-phase permanent magnet motor |

| Environmental Requirements | Temperature -25℃~85℃ |

| Humidity 20%~85%RH | |

| The atmospheric environment does not produce strong magnetism, no corrosion,no explosive gas, no oil mist, no dust; the altitude is below 1000 meters. |

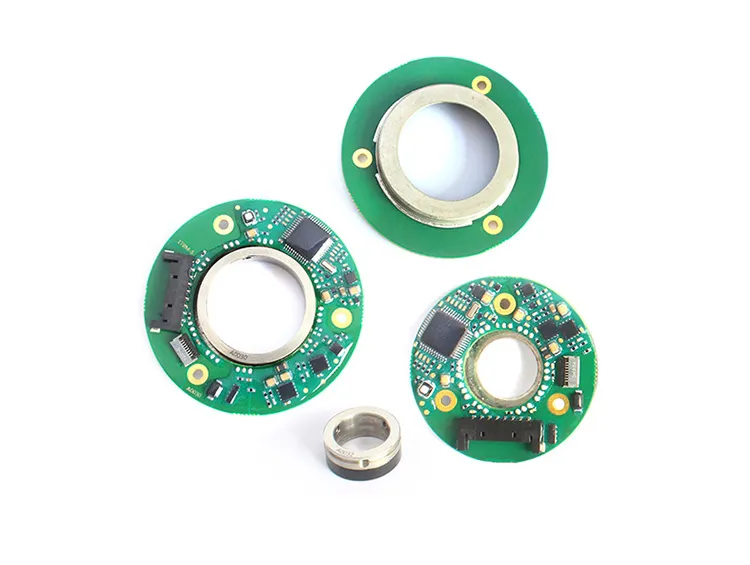

Frequently bought together - Magnetic encoders

Direct drives need high-quality position signals to ensure optimal performance. Perfect measuring signals can enhance the surface quality of machined workpieces, reduce the machine frame's vibrations, minimize velocity-dependent motor noise, and prevent excessive heat generation in the motor.

Mosrac recommends using a magnetic encoder to enhance the accuracy, speed stability, and thermal behavior of direct drive axes. Because there is no mechanical transmission between the encoder and the feed unit, the position signals are not susceptible to inaccuracies or delays.

Custom combinations are available on request and contact us.