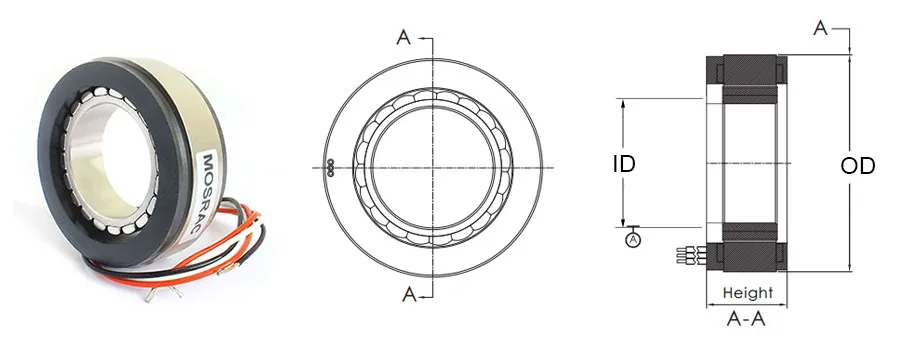

Parameter table of frameless inrunner torque motors

The standard frameless motors from Mosrac are very compact in design and lightweight with excellent performance of high precision, high overload capacity, and high torque density. These motors have industry-leading performance and are cost-effective. Additionally, if the performance and cost differ, we offer customized solutions to control your product costs better.

In the standard U series, Mosrac offers frameless motors that come with voltage ranges from 24 to 220V, outside diameters from 25 to 200mm, continuous torque values from 0.025Nm to 50Nm, and peak torque capabilities reaching up to 1000Nm.

The table below summarizes the main specifications. Click the "model number" to check technical files including catalog, 3D, and CAD drawings for each frameless torque motor.

| Model | OD(mm) | ID(mm) | Height(mm) | Weight(kg) | Rated Torque(Nm) | Rated Power(W) | Rated Speed(rpm) | Voltage(V) |

| U1919 U1934 |

19 | 7 | 19.9 34.9 |

0.024 0.042 |

0.02 0.04 |

13 17 |

4000 8000 | 24 |

| U2510 U2515 U2523 |

25 | 11.6 | 10.8 15.2 23.4 |

0.024 0.036 0.052 |

0.025 0.05 0.075 |

10 21 31 |

4000 | 24 |

| U3815 U3822 U3834 |

38 | 18 | 15.3 22.3 34.3 |

0.048 0.068 0.099 |

0.1 0.2 0.35 |

31 63 110 |

3000 | 48 |

| U5019 U5024 U5037 |

50 | 28 | 19.8 24.3 37.9 |

0.12 0.157 0.266 |

0.27 0.42 0.7 |

85 132 220 |

3000 | 48 |

| U6017 U6022 U6035 |

60 | 33 | 17.7 22.2 35.8 |

0.146 0.205 0.361 |

0.45 0.6 0.96 |

141 189 302 |

3000 | 48 |

| U6818 U6822 U6836 |

68 | 37 | 18.3 22.8 36.4 |

0.197 0.266 0.474 |

0.63 0.86 1.54 |

198 270 484 |

3000 | 48 |

| U7618 U7623 U7636 |

76 | 42 | 18.6 23.1 36.7 |

0.245 0.333 0.606 |

0.89 1.23 2.06 |

280 387 648 |

3000 | 48 |

| U8519 U8523 U8537 |

85 | 47 | 19.3 23.8 37.4 |

0.306 0.414 0.736 |

1.21 1.65 2.69 |

380 519 846 |

3000 | 48 |

| U9419 U9424 U9437 |

94 | 42 | 19.7 24.2 37.8 |

0.382 0.522 0.93 |

1.58 2.05 3.67 |

497 645 577 |

3000 | 48 |

| U11526 U11530 U11544 |

115 | 65 | 26.3 30.8 44.4 |

0.655 0.85 1.45 |

3 3.9 6.1 |

943 1022 959 |

3000 2500 1500 |

48 |

| U13025 U13035 U13060 |

130 | 84 | 25.9 35.9 60.9 |

0.9 1.3 2.7 |

5 9 18 |

419/1048 472/1415 755/1509 |

800/2000 500/1500 400/800 |

48/220 |

| U16025 U16035 U16060 |

160 | 106 | 25.9 35.9 60.9 |

1.1 1.6 3.3 |

9 15 32 |

472/1886 472/1258 671/2012 |

500/2000 300/800 200/600 |

48/220 |

| U20025 U20035 U20060 |

200 | 140 | 25.9 35.9 60.9 |

1.7 2.9 5.5 |

13 24 50 |

409/1090 503/1258 524/1572 |

300/800 200/500 100/300 |

48/220 |

Case studies (Customized frameless motors developed with our clients)

Frameless inrunner torque motor solutions

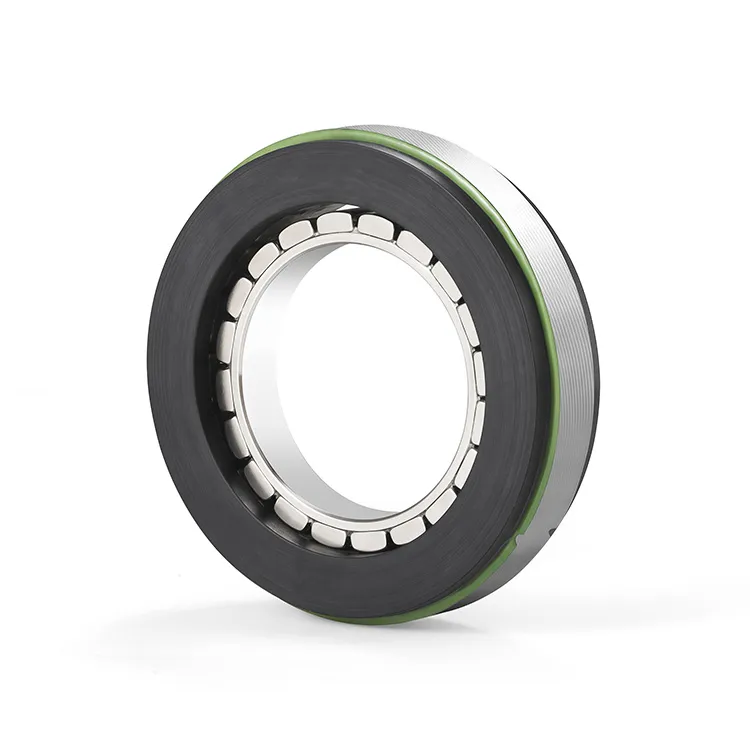

Mosrac specializes in designing & manufacturing frameless (inrunner) torque motors. This design allows the rotor and stator to be integrated directly into the application or assembly, offering maximum flexibility, lightweight, and compact size.

Mosrac is also well-known for developing high-quality special and fully customized torque motors with an outrunner or inrunner design to meet personalized application needs such as space-limited applications and special engineering projects, perfectly matching your facility spacing & industry needs.

Mosrac’s direct-drive frameless brushless (inrunner) torque motors help you achieve your ideal torque, speed, size, and temperature for robotics (most for cobots & humanoid robots), medical devices, aerospace systems, and more.

-

U19 Series 19MM Motore FramelessU25 Series 25MM Smallest Frameless MotorsU38 Series 38MM Frameless Torque MotorU50 50MM Series Frameless Servo MotorU60 60MM Series Frameless BLDC MotorU68 68MM Series Frameless Rotary MotorsU76 Series Brushless Frameless DC MotorU85 Series Frameless Brushless MotorU94 Series Frameless Inrunner Torque MotorU115 Series Frameless BLDCU130 Series Frameless Direct Drive MotorU160 Series Frameless Brushless DC MotorU200 Series Direct Drive Frameless Motors

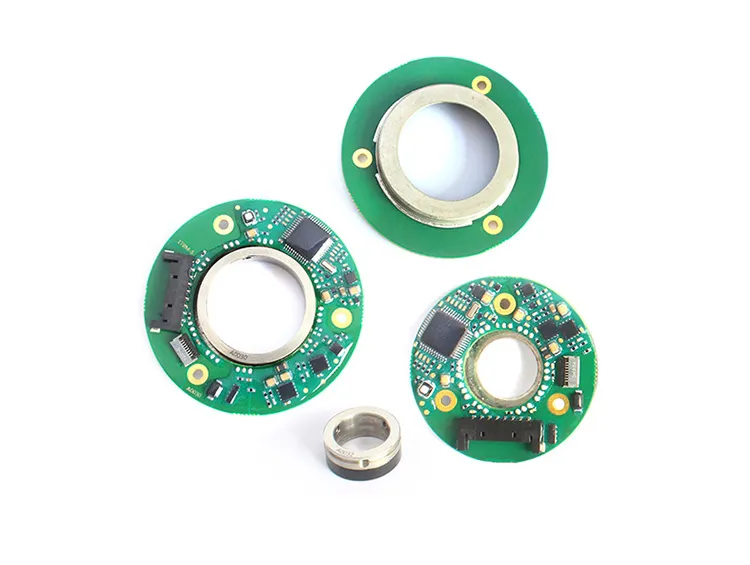

Related products - magnetic encoders & outrunner motors:

Direct drives need high-quality position signals to ensure optimal performance. Perfect measuring signals can enhance the surface quality of machined workpieces, reduce the machine frame's vibrations, minimize velocity-dependent motor noise, and prevent excessive heat generation in the motor.

Mosrac recommends using a magnetic encoder to enhance the accuracy, speed stability, and thermal behavior of direct drive axes. Because there is no mechanical transmission between the encoder and the feed unit, the position signals are not susceptible to inaccuracies or delays.

Custom combinations are available on request and contact us.

Download

Features:

- More than 100+ standard sizes are available

- 12 standard frame sizes from 25mm ( 0.984 inches) to up to 200mm (7.874 inches). ( see above table).

- Custom frame sizes are available for OEM applications

- 12 frame sizes to meet the most popular embedded equipment & collaborative robot (cobot) designs

- Speeds up to 6,000 rpm

- Pole Count from 4 to 64 Poles or custom

- Designed for operation at 24VDC, 48 VDC, and custom voltage range from 24VDC to 380VDC

- Continuous torque range from 0.025 Nm to 50 Nm or custom, Peak torque reaching up to 1000Nm

- High-temperature resistance, Available in low voltage and high voltage, Lower thermal resistance

- Stainless steel rotors for corrosion protection

- Multiple standard windings with custom windings available upon request

- Low Cogging designs

- Ideal for joint of robotic arms and robots

- CE, RoHS, REACH compliant

- Optional Hall sensors or encoders as rotor position feedback devices

- Standard and custom windings to match special speed and torque performance requirements

- Frameless models use the load’s shaft and bearings and can include Hall sensors, and additional position feedback devices such as encoders can be added as separate components

Benefits:

- The thin, adaptable, and compact design reduces both minimum machine size and maintenance, as the load and motor share the same set of bearings, simple mounting, and assembling.

- Direct drive and brushless design significantly decrease rotor inertia, leading to enhanced acceleration.

- High torque density ensures the production of a magnetic field twice as strong as ferrite magnets.

- Standard or custom windings ensure stable torque delivery even at slow rotation rates.

- Optional for low-speed and high-speed windings can enhance versatility and performance across various applications.

- Low cogging ensures smooth low-speed rotation. - Low cogging torque for a smooth, steady operation

- High-cost performance ensures that customers receive significant value for their investment between performance, quality, and price.

- Enhanced cooling and efficiency boost performance in a wide variety of operating conditions.

- Easy machine integration - All U-series motors are supplied as two pieces – a slotless stator coil and a permanent magnet rotor. The hollow rotor mounts

- Directly to a drive axis with no gearing required.

- Hollow shaft design - frameless version and easy to be integrated

- High dynamics

- Optimal speed control

- Low maintenance

- Quiet operation

- High reliability and lifetime

Applications:

Below are some examples of industry applications where torque motors are successfully used, providing our customers in these areas with a distinct competitive advantage.

- High-speed milling / turning tables

- High precision machining centers

- Grinding/finishing machines

- Boring / drilling/tapping machines

- Milling heads

- Transfer lines

- EDM

- Laser / ultrasonic cutting machines

- Stamping machines

- Lathes

- Indexing tables

- Electronic chip testing equipment/Electronics

- Pick-and-place machinery

- High-end printing/scanning machines

- Packaging equipment

- Handling equipment

- Composite materials manufacturing

- Telescopes

- Semiconductor

- Wind turbines

- Robotics/robotic joints

FAQs:

Order starts from 1 piece, MOQs (minimum order quantity) of mass production are based on the cost of tooling and setup for our factories to produce standard or custom motors.

To initiate a trial order or reorder, kindly establish communication with your assigned Product Specialist, who assisted you during your initial order placement. Alternatively, you can direct any inquiries regarding reordering to sales12@mosrac.com, where a dedicated Product Specialist will be pleased to provide further assistance.

To determine the correct motor size, please check the drawings or download technical files from each U series frameless motor category. Alternatively, you can direct any questions regarding specifications to sales12@mosrac.com, where a dedicated Product Specialist will be pleased to provide further assistance.

Yes, we do!

High-quantity orders generally net a lower cost-per-unit (higher quantity = bulk savings) on all of our torque motors orders.Mosrac offers extended standard or custom variants of frameless torque motor options. Within these motor options, we also have an array of styles to serve all concerns and torque motor needs.

Here are the lines of torque motors we currently offer:- Inrunner frameless motors

- Outrunner frameless motors

- Custom frame sizes for frameless motors

- Custom pole count for frameless motors

- Custom voltage range for frameless motors

- Custom windings for frameless motors

We always provide CAD and 3D digital proofs to you for approval before moving forward to prototyping or mass production. By using the 3D digital proof, you can get a general idea of exactly what your torque motor will look like after manufacturing and assembly.

If you are ordering a large volume order and are unsure of how the finished product would look like, we suggest requesting a production-grade sample of your motor to ensure that your motor is exactly the way you want it before moving to mass production.

Our sales representatives are available from Monday - Saturday @ 9:00 am - 7:30 pm (GMT+8)

Call our by mobile phone at +86 18100274370

Speak to us through our WhatsApp at +86 18100274370 (online live chat)

Send an email to sales12@mosrac.com

Our headquarters are located in Shenzhen, China. However, we manufacture, ship, and offer our services internationally.

Our manufacturing facilities are located in Shenzhen, China.

We have two prototyping options available for our customers;

- Digital 3D mockups

- Production-grade prototypes

In our current situation, we are not able to provide accurate pricing for our prototypes due to each customer's customizations (type of torque motor, performance, specs, and additional processes). To get pricing on our prototypes and samples, we recommend reaching out to our Product Specialist.

Have other questions for us? Ask our experts directly!

Have other questions for us? Ask our experts directly!How to order:

Torque Motor Series

U: Frameless torque motor

123456789Cable length

03:300mm

00: please consult for custom lengthStandard/Customized

None: Standard

C: CustomizedVoltage

48:DC48V

24:DC24V

(except u25 series, custom for other series)

12:DC12V

(Please consult for a custom voltage range)Environmental:

Default: -25℃~85℃

Please consult for a custom temperature rangeTemperature control

Nothing: w/o temperature control

T: w/ temperature controlEncoder type

H: Hall

E: Photoelectric incremental (analog)

E1: Photoelectric incremental type (digital)

E2: Photoelectric absolute type

S1: 17-bit magnetic encoder

S2: 24-bit magnetic encoder

T: 24-bit magnetic dual encoderRated torque

for example: 0.2Nm, 3Nm, 15Nm, or customSize:

for example:

Height: 10.8mm, 30.8mm, or custom

OD: 25mm,115mm, or customRotor type

I: inner rotor

E: outer rotor

eg:

UI:inner rotor frameless motor

UE:outer rotor frameless motorFor example

U3815: U series frameless torque motor, OD 38mm, height 15.3mm, rated torque 0.1Nm, inner rotor;

U11544: U series frameless torque motor, OD 115mm, height 44.4mm, rated torque 6.1Nm, inner rotor;

UE2506: U series frameless torque motor, OD 25.3mm, height 6.2mm, rated torque 0.04Nm, outer rotor;