As robots become more advanced, they need components that can help them move in very precise and powerful ways.

Frameless direct-drive torque motors are reliable because there are no extra transmission parts. They can also achieve very fast speed and acceleration, making them well-suited for robotics applications where precise positioning and repeatable movements are important.

Collaborative Robots (Cobots)

The dual-arm YuMi robot sits side by side with people, boosting flexibility and competitiveness at Deonet, a Dutch manufacturer. Source: ABB

Cobots are designed to work safely alongside humans in environments like factories and warehouses. Their joints require extremely precise torque control to avoid pinching or hitting people. Frameless direct drive motors provide the speed, accuracy, and torque sensing needed to smoothly handle payloads, open/close grippers, and more in close human proximity.

Mobile Robots

Boston Dynamics' robot dog Spot is displayed at CES 2022, the world's largest annual consumer technology trade show, held in Las Vegas.

TAYFUN COSKUN/ANADOLU AGENCY VIA GETTY IMAGES

Whether navigating hospital floors to deliver supplies or roaming warehouse aisles to find inventory, mobile robots rely on compact yet powerful drive motors. Frameless direct drive torque motors are well-suited, providing high torque output to move the robot body and integrated positioning feedback to steer and control speed precisely.

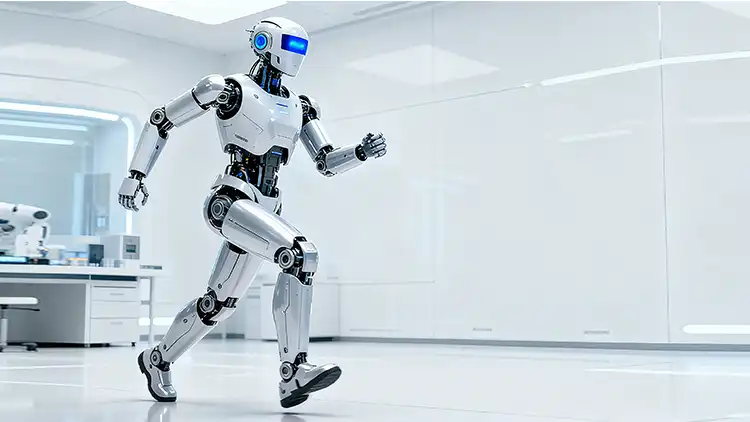

Humanoid Robots

A humanoid robot serving food in the kitchen

As robots take on more human-like forms, replicating natural human motion is essential. The nimble, zero-backlash movement of frameless direct drive joints enables humanoid robots to walk, balance, gesture, and emulate realistic human mannerisms. They can also interface directly with robot microcontrollers to provide advanced torque control.

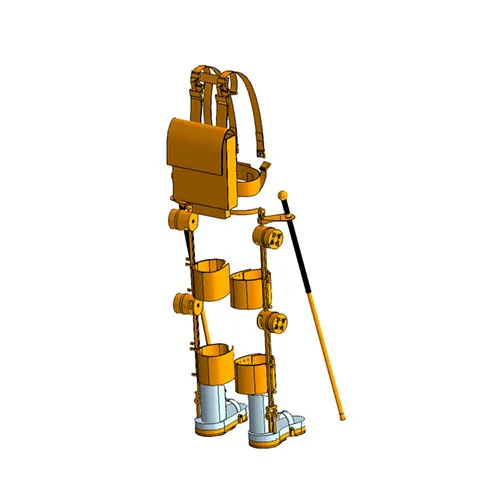

Exoskeleton

Lower-profile motors are important for exoskeleton comfort and operation to assist those with disability or injury. Frameless direct drives meet this need while providing the torque required to power leg, arm, and hand movements that easily mimic natural human abilities.

The exoskeleton robot is different from humanoid and collaborative robots. It is a wearable robot that can be worn on the body like clothing. It is designed to enhance the wearer's motion and strength. This kind of robot is commonly used in medical training, special handling industries, and military applications. Its key components include the frameless torque motor.

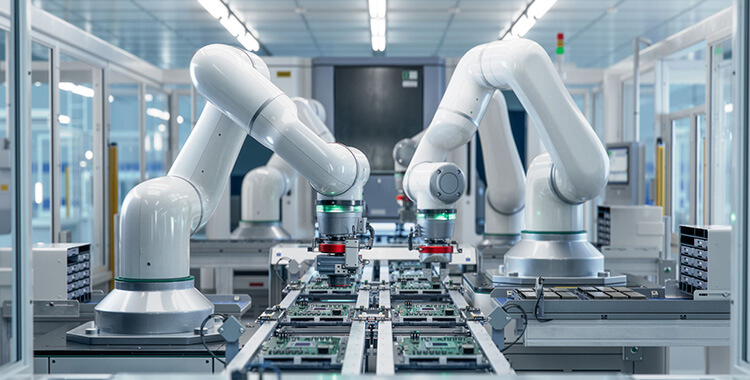

Industrial Robots

An industrial robot working on a production line

Factories rely on industrial robots and their direct drive motors to weld, assemble, and handle tasks that are too dirty or dangerous for humans with swift accuracy. These motors ensure repeated precision in 6-axis robotic motions for high-volume production applications like automotive manufacturing. Their torque handles rigorous payloads with minimal footprints.

SCARA Robots

The Epson GX-B SCARA robots become the flagship SCARA robots in the Epson lineup. | Credit: Epson

Frameless direct drives are a popular motor choice for SCARA (Selective Compliant Assembly Robot Arm) robots. They support their precise pick-and-place function with high speed and acceleration. The compact motors are located at each joint, allowing intricate SCARA robotic motions in tight workspaces.

As these applications grow more complex, so does the need for a reliable partner. Mosrac has decades of experience solving diverse engineering challenges. To learn how our frameless torque motors could augment your innovation, visit our website or connect with our application experts.